All

Check-Weigher

Full Description

The Checkweigher 08T3 offers extremely versatile and functional weight control for small to medium-sized products, featuring a user-friendly touch-screen panel. With a maximum capacity of 3200 g, precision starting from ± 0.5 g, and a production rate of up to 300 ppm, this dynamic scale delivers high performance and reliability for metrological control of a wide variety of pre-packaged products such as trays, bags, cans, bottles, and boxes of different shapes and sizes.

Constructed entirely of stainless steel and rated IP65 for protection, the 08T3 is highly configurable, thanks to numerous optional features. The dual load cell weighing system ensures high precision and repeatability, even at high speeds, while also facilitating easy cleaning and maintenance. Advanced digital electronics with a touch-screen panel provide intuitive operation, with features such as storage for up to 200 product programs. Additionally, the machine supports external communication through RS232 C serial ports and an Ethernet interface.

The Checkweigher 08T3 is built on a stable, tubular stainless-steel structure that minimises vibrations and disturbances from the work environment. With over 30 years of experience in inspection and quality control, this machine meets the highest standards of performance, quality, and regulatory compliance, making it a reliable choice for various industries.

Technical Data

- Model: 08T3 Checkweigher

- Flow Rate Range: Up to 3200 g

- Display Division: Starting from 0.5 g

- Linear Speed: Up to 100 m/min

- Production Rate: Up to 300 ppm

- Precision: Starting from ± 0.5 g

- Pneumatic Power Supply:6 Mpa

- Air Consumption (for Ejection): 1 Nl

- Electrical Supply: 230V, 50/60Hz, single-phase

- Power Consumption: 700 W

- Finish: Stainless steel, IP65

- Operating Temperature: From 5°C to +40°C without condensation (closed)

Videos

Technology

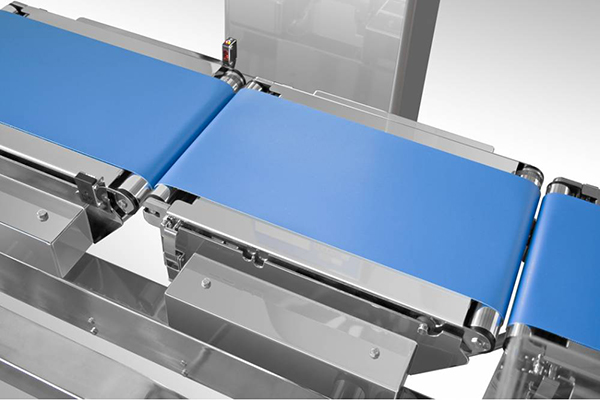

Dual Load Cell System

Weight detection occurs through a double load cell system, ensuring high precision and repeatability even at high speeds. This configuration also facilitates easy cleaning and maintenance, reducing downtime and maintenance costs.

Wind Protections

High-resistance fairings protect the instrument against environmental factors and pollutants, maintaining optimal operating conditions.

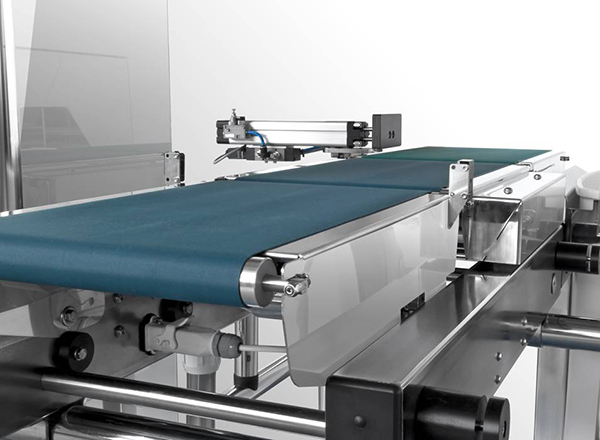

Quick-Release Tapes

A mechanical fastening and unlocking system that drastically reduces machine downtime, both during cleaning and when replacing the belts.

Product Program Memory Expansion

The limit of 100 product programs can be exceeded by expanding the available memory, further increasing the versatility of the machine.

Key Features

End of Line Add-Ons

Browse Compatible Machines

From palletizers to labellers, finalise your production line with automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.