Special Applications

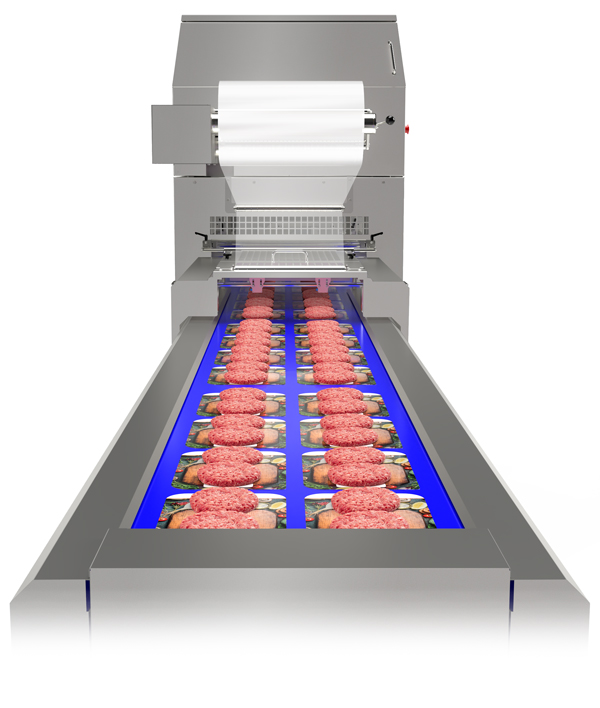

FoodPack FastBoard

Full Description

FoodPack FastBoard is the new ILPRA FoodPack revolutionary model. It allows flat board containing the product to be moved by simply placing them on a belt, without the need for jaws. The sealing mould, unlike the moulds used on the market, doesn’t need a lower part that moves upwards, but the sealing operation is done only through the upper bell that closes directly on the belt. The possibility of adjusting the starting height of the bell, depending on the product to be packaged, makes it possible to obtain the highest possible speed by optimising the closing phase.

This ILPRA model completely revolutionises the skin packaging concept of the conventional in-line tray sealers on the market. High productivity, flexibility of use and cost reduction are the major strengths of this new technology, which respects ILPRA’s philosophy of uncompromising packaging quality.

Technical Data

Technical Data : FoodPack FastBoard

Dimensions: 597 x 97 x h 204 cm

Weight: circa 1900 Kg

Air Consumption: 6 bar – 80 Nlt/cycle

Sealing Area: 1130 x 400 x protrusion height 70 mm

Videos

Technology

E-MEC Technology

Enhances the machine’s speed and productivity through fully electromechanical movement.

PROGAS System

Patented by ILPRA, this system ensures lower gas usage and faster operation speeds.

ID Control System

Offers secure access with badge-based recognition, including multiple identification levels.

Predictive Maintenance System

Facilitates proactive planning for component maintenance and replacement.

ExtraSkin System

Allows for advanced skin packaging, even with high degrees of protrusion.

Optional: Pre-Heating System

Optimises skin packaging by pre-heating the film, enhancing efficiency.

DETAILS

End of Line Add-Ons

Browse Compatible Machines

From palletizers to labellers, finalise your production line with automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.