In Line

FoodPack 1450

Full Description

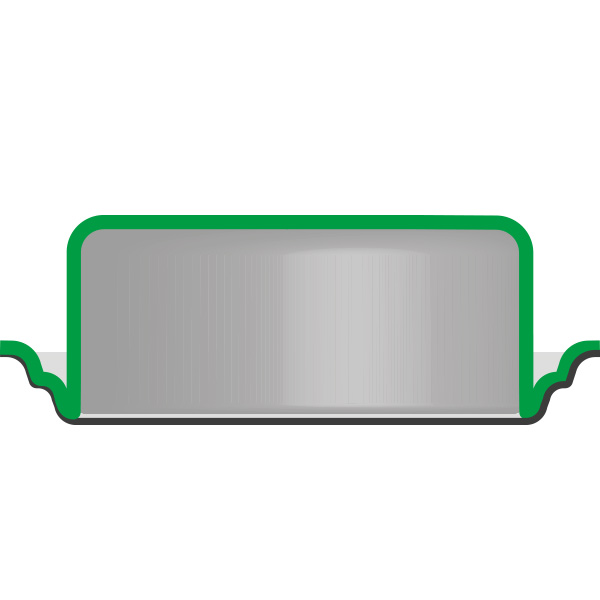

This is an efficient in-line machine, capable of handling three 187×137 mm containers simultaneously. This versatile machine is designed to accommodate a variety of packaging applications, including fruit, meat, ready meals, and fish.

The FoodPack 1450 stands out as a high-performance, automatic in-line tray sealer, embodying the perfect blend of reliability and versatility for businesses aiming to elevate their packaging operations. Its design facilitates easy integration into existing production lines, enabling the packaging of a diverse range of products with its expansive sealing area and user-friendly operation.

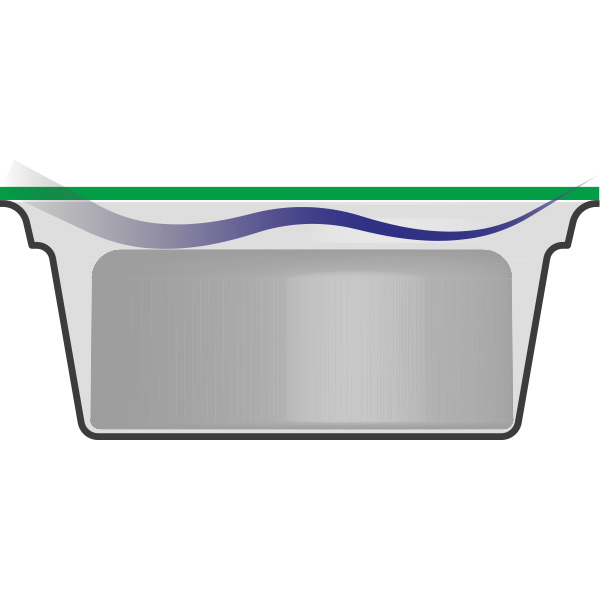

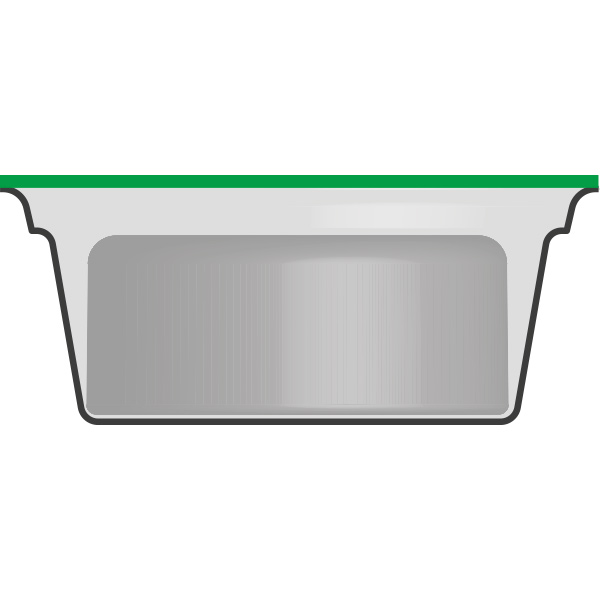

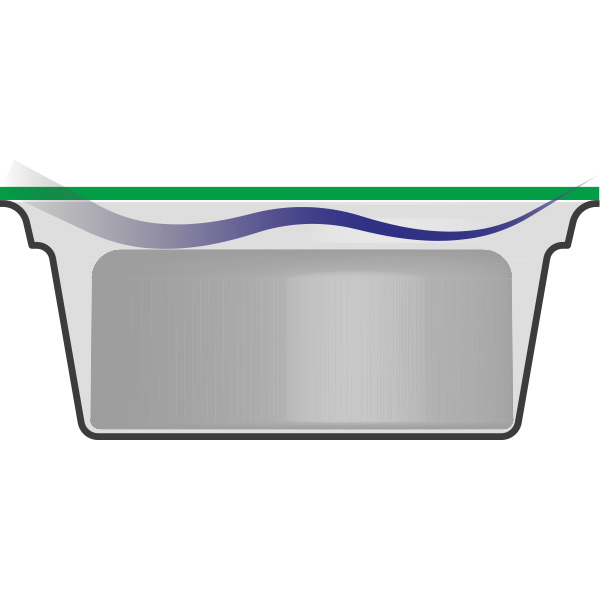

Gas Flush

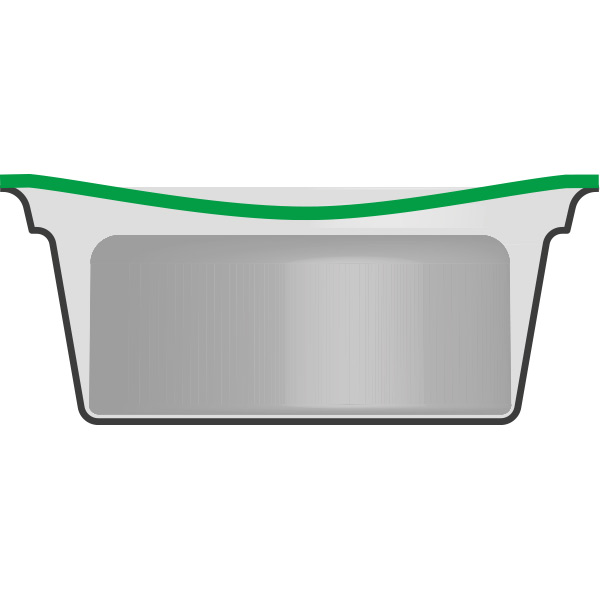

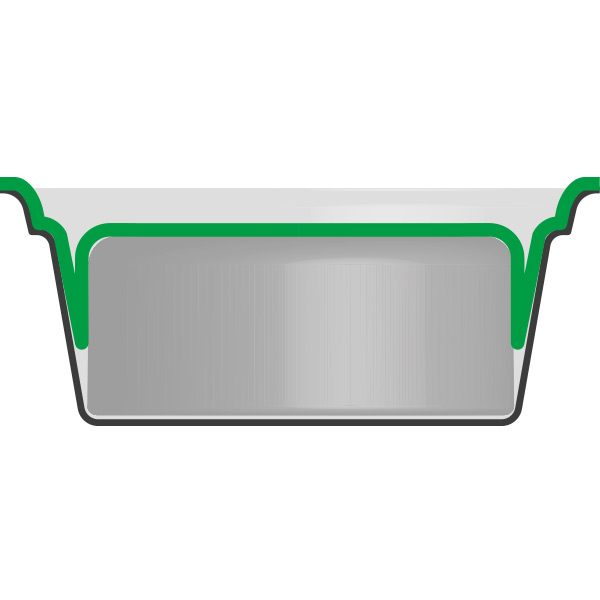

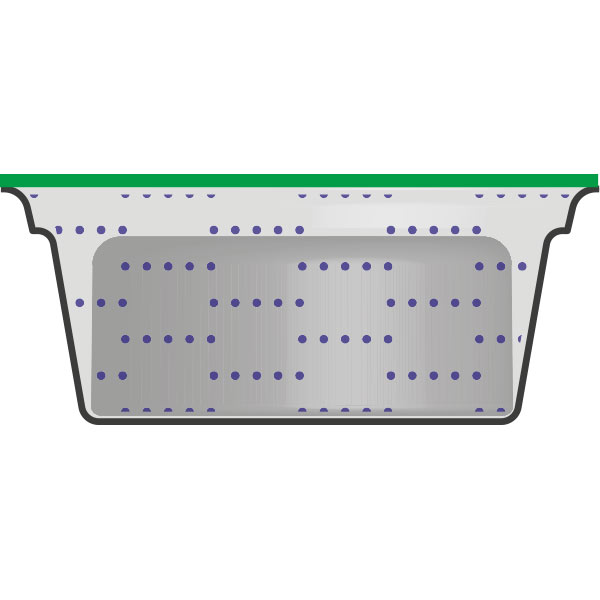

Vacuum

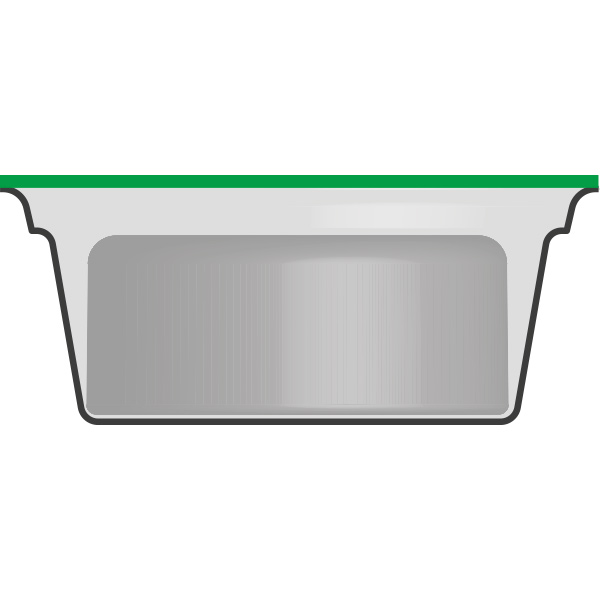

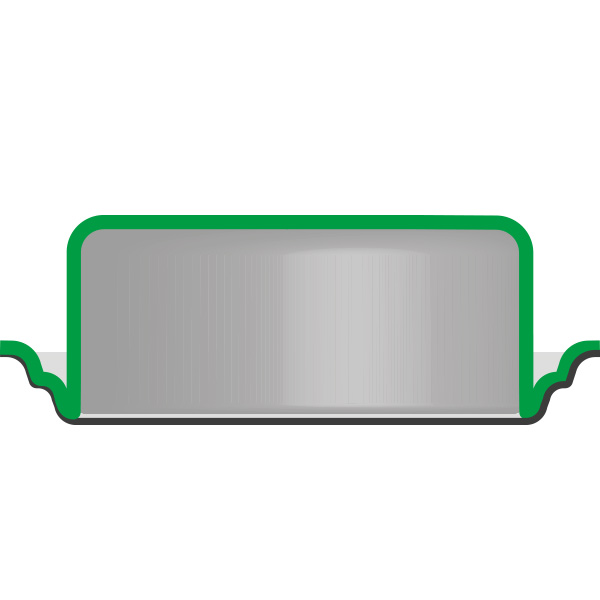

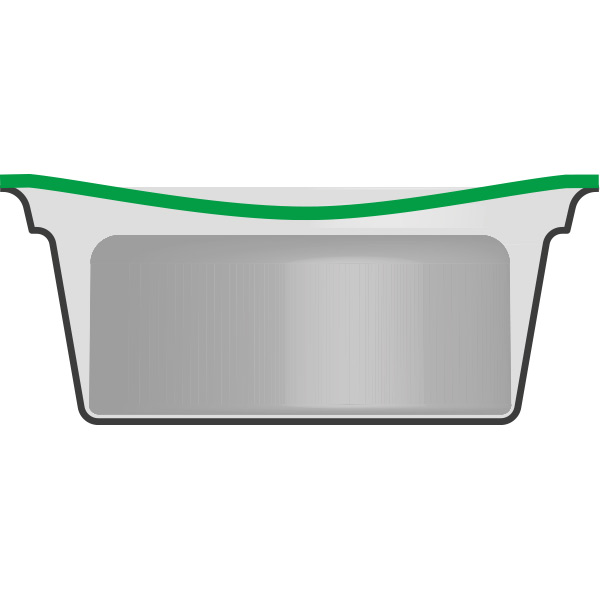

Sealing

MAP/ATP

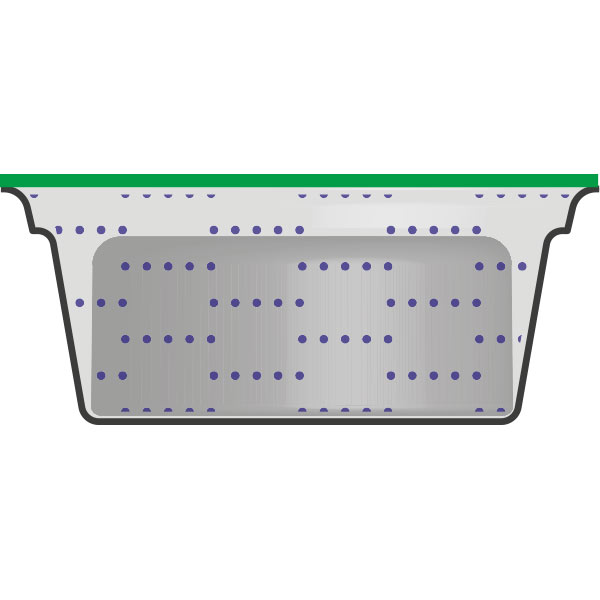

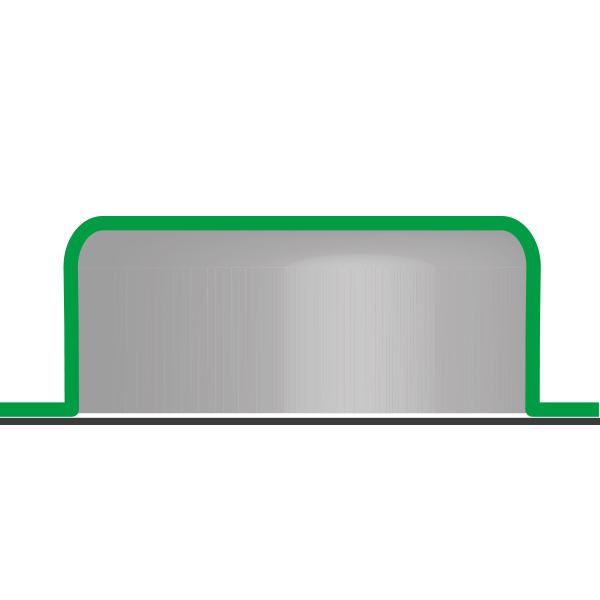

Skin

Overskin

Extraskin

Extraskin on Cardboard

Sealing

Up to 25 cpm

Gas Flush

Up to 22 cpm

MAP/ATP

Up to 15 cpm

Vacuum

Up to 22 cpm

Skin

Up to 8 cpm

Overskin

Up to 7 cpm

Extraskin

Up to 6 cpm

Extraskin on cardboard

Up to 6 cpm

Technical Data

Technical Data : FoodPack 1450

Dimensions: 331 x 90 x h 190 cm

Weight: 1500 Kg

Air Consumption: 6 bar - 5 Nlt/cycle

Sealing Area: 560 x 350 x h 120 mm

Videos

Technology

E-MEC Technology

This fully electromechanical movement technology at the workstation boosts both speed and productivity significantly.

PROGAS System

A patented ILPRA innovation, the PROGAS System reduces gas consumption while enhancing operational speed, and is a standard feature across this product line.

Constant Placement System

This advanced technology ensures a steady flow of trays into the machine, with belt and jaw interpolation that notably increases production speed.

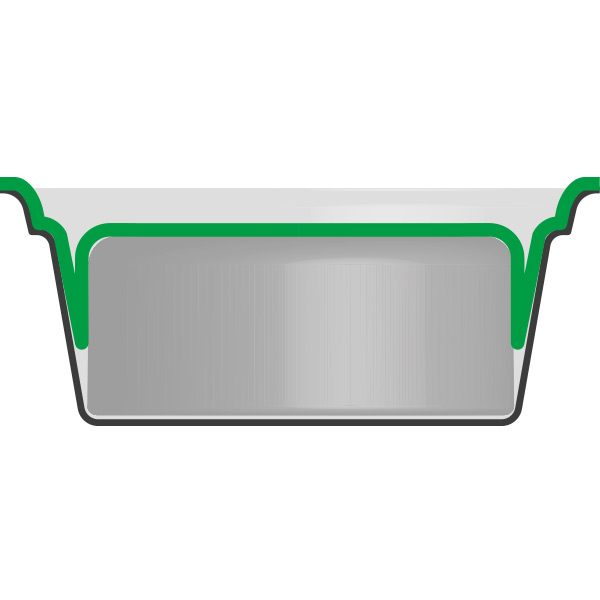

Optional: EXTRASKIN System

Enables skin packaging at high protrusion levels, expanding packaging possibilities.

Optional: Pre-Heating System

Optimises skin packaging by pre-heating the film, improving packaging quality and efficiency.

Optional: Predictive Maintenance

A forward-thinking system that schedules maintenance and component replacements, enhancing machine longevity and reliability.

Optional: ID Control System

Enhances security by using badge recognition to identify authorised personnel, with up to three levels of access.

Optional: Anti-Crush System

Prevents damage to trays by halting the sealing process if trays are misaligned, ensuring product integrity.

DETAILS

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.