Special Applications

FoodPack Speedy +

Full Description

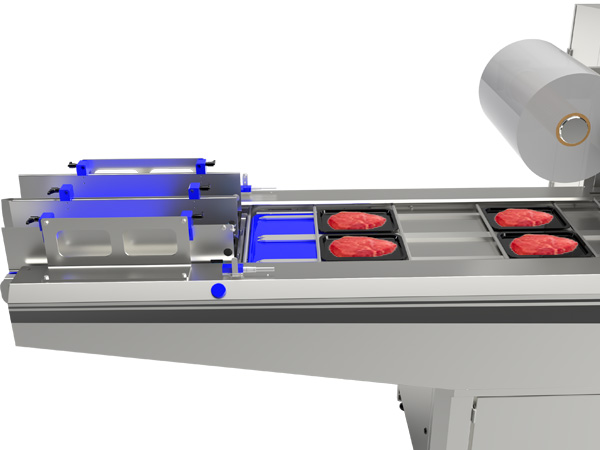

The FoodPack Speedy + is a refined version of the popular FoodPack Speedy, now designed as an in-line tray sealer. This model integrates seamlessly into production lines, enhancing performance with a double chain transport system. It surpasses the performance of its predecessor, the FoodPack Speedy PN20, while maintaining precision in container handling.

Ideal for those seeking an automated solution without a significant budget increase, the Speedy + offers an efficient and cost-effective packaging option.

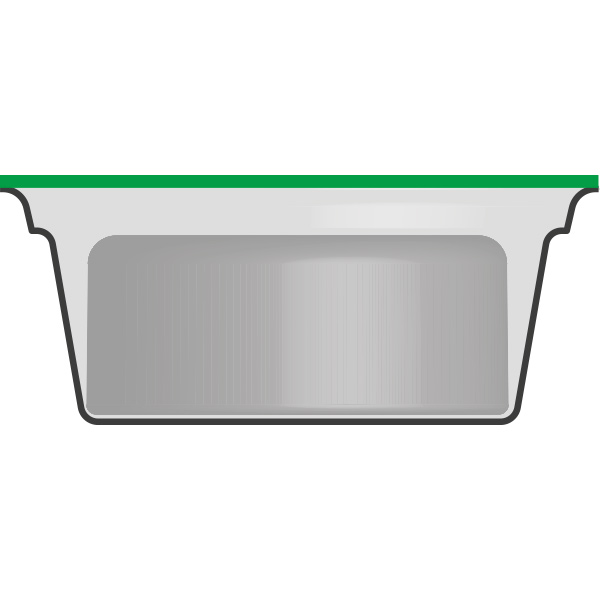

Sealing

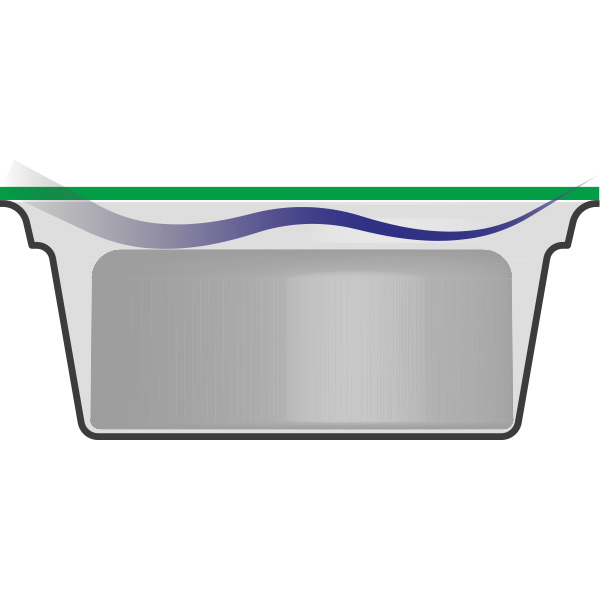

Gas Flush

MAP/ATP

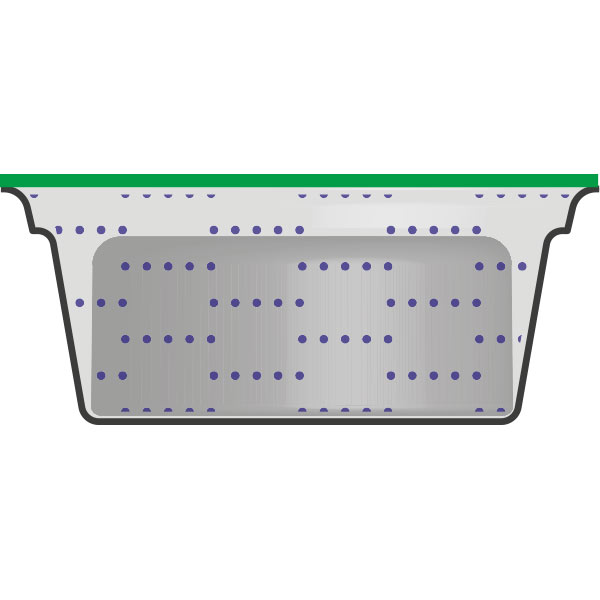

Vacuum

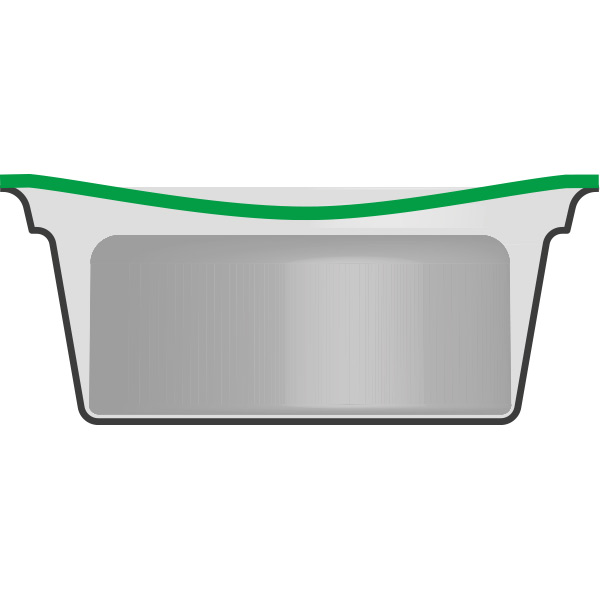

Skin

Overskin

Extraskin

Extraskin on Cardboard

Technical Data

Technical Data: FoodPack Speedy +

Dimensions: 287 x 106 x h 158 cm

Weight: 600 (N) / 680 (VG) Kg

Air consumption: 6 bar - 35 (N) / 40 (VG) Nlt/cycle

Sealing area: 380 x 270 x h 135 mm

Videos

Technology

PROGAS System

This ILPRA-patented technology enhances the machine’s efficiency by reducing gas usage and increasing operational speed, available across all models in this line.

E-MEC Technology

Based on fully electromechanical movements, this technology boosts the machine’s speed and productivity, ensuring high-performance output.

Optional: ExtraSkin System

Enables advanced skin packaging, accommodating products with high protrusion, adding versatility to the packaging capabilities.

Optional: Pre-Heating System

Optimises skin packaging by pre-heating the film, improving efficiency and packaging quality.

DETAILS

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.