Automatic

VKF90 Thermoformer

Full Description

The VKF90 thermoforming machine is a leading solution for large production requirements, offering seamless integration with complete packaging lines and interaction with various elements like automatic dosing systems and automatic loading systems.

Its design caters to the needs of large companies seeking high-level automation in packaging operations. Constructed from stainless steel AISI 304 and equipped with a brushless motor, the VKF90 ensures reliable transportation of plastic film and features both mechanical and pneumatic or electrical lifting systems for sealing and forming moulds.

The machine is controlled and managed via a 12” touch screen control panel, with a tensioning system for pre-unwinding of the plastic film. It supports packaging in both flexible and rigid plastic materials, with capabilities for linear and perimetric cuts.

Advanced HMI with Total Quality Control (TQC) systems, a synoptic system for production standards monitoring, and vacuum performance analysis for total control on the machine, make the VKF90 a comprehensive solution for sealing, skin with or without edge, MAP, and vacuum packaging applications.

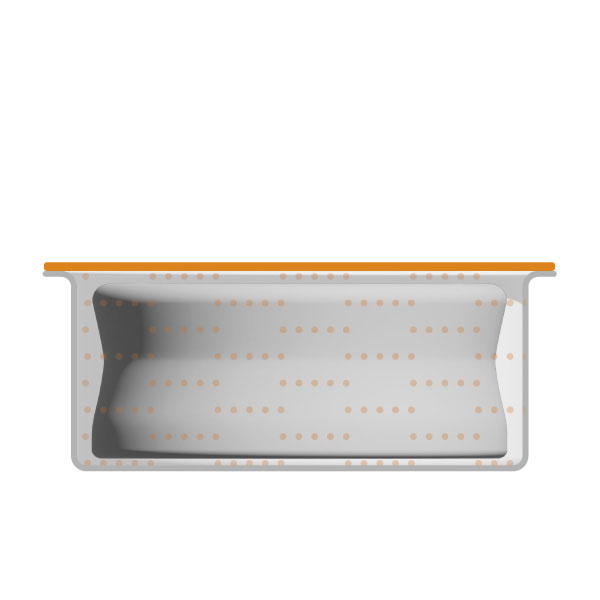

Skin Form

Sealing Form

MAP/ATP Form

Vacuum Form

Technical Data

Machine length: From 7435 to 21435 with step of 600 mm

Machine width: 1190 ÷ 1390 mm

Machine height (luminous turret excluded): 1970 mm (± 50 mm)

Loading area: According to user’s needs

Loading area height: 950 mm (± 50 mm)

Machine weight (vacuum pump excluded): From 2500 Kg

Control panel height: 1500 mm (± 50 mm)

Lower film standard width: 322, 362, 422, 462, 522, 562, 622 mm (+1 mm)

Lower film special width: 222 ÷ 622 mm (increments 5 mm)

Feeding max. step: 1100 mm

Forming max. depth: 200 mm

Film reel core diameter: 3″ (70 ÷76 mm)

Lower film reel max. diameter: 500 mm

Upper film reel max. diameter: 400 mm

Construction: Stainless steel Aisi 304

Control / command system: PLC and Touch Screen 12″

Control / command interface: HMI Simatic Siemens – Windows CE

Feeding system (Drive): Brushless Motor

Installed power (pumps excluded): 20-40 kW – 440 V – 50/60 Hz – 3P+N+GND

Protection degree IP / NEMA: IP 66 / NEMA 4

Pneumatic feeding (average consumption): 2500 Nl/min

Electrical components: Siemens, Toshiba, ABB, Sick, Phoenix Contact

Mechanical components: Rossi motoriduttori, Minimotor, Siemens, Iwis, SKF, Igus

Pneumatic components: Festo, Parker

Vacuum system components: Omal, Valvaut, Maros Engineering, Trelleborg

Packaging Details

Production capacity: Up to 28 cycles / min.

Application: Sealing, Skin, MAP, Vacuum

Lower film for rigid packages: Up to 1000 µm (PET, PVC, PS, PP)

Upper film for rigid packages: Up to 450 µm

Lower film for flexible packages: Up to 400 µm (PA, PP, Paper, Alu)

Upper film for flexible packages: Up to 200 µm (PA, PP, Paper, Alu, Tyvec, Skin)

Videos

Technology

Large-Scale Production Adaptability

Engineered for the high automation and productivity demands of large enterprises, the VKF90 supports expansive packaging operations with sophisticated technology.

High Automation Integration

Designed for high-volume operation with seamless integration into complex packaging lines, enhancing efficiency and system compatibility. .

Tool-Free Configuration

Facilitates rapid adjustments and format changes without tools, significantly boosting operational flexibility and productivity.

AISI 304 Stainless Steel Construction

Features durable construction with AISI 304 stainless steel, ensuring longevity and reliability in demanding production environments.

Advanced HMI with Touch Screen Control

Incorporates a 12” touch screen control panel and an intuitive Human-Machine Interface (HMI), developed in Windows CE on SIEMENS SIMATIC systems, for ease of use across all operator levels.

36-Month Warranty

Offers a standard 36-month warranty, demonstrating commitment to quality and durability.

IP66 Rated for Sanitisation

Designed to withstand intensive sanitisation processes, suitable for industries requiring high hygiene standards, with an IP66 rating.

End of Line Add-Ons

Browse Compatible Machines

From palletizers to labellers, finalise your production line with automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.