What to Expect

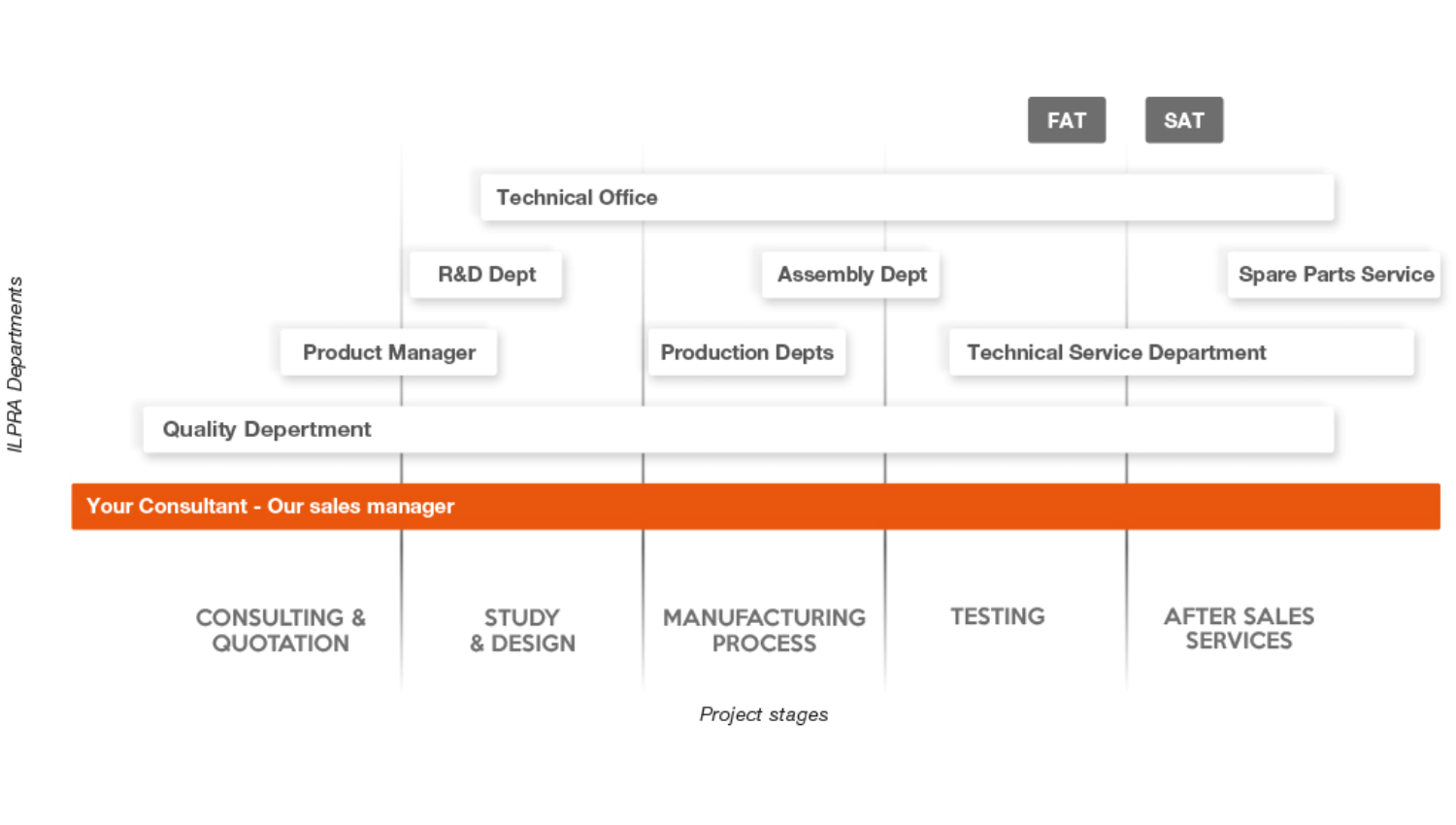

The ILPRA Method

Every packaging project is different, but the goal stays the same: deliver the right solution for your production, with quality you can rely on. Our process is designed to keep things structured and efficient, while still giving you a tailored result based on what you actually need.

Our Process

How We Work

Consultation & Quotation

We begin by understanding your product, packaging requirements and production environment. This includes important details like pack format, shelf-life needs, output targets and any challenges you’re currently facing. Your request is reviewed with technical input to confirm feasibility and find the right approach, whether that’s a standalone machine or a wider packaging line solution.

Design

Once the project direction is agreed, we shape the packaging solution around your production needs. This stage focuses on both performance and practicality, ensuring the final setup works smoothly day to day. We look at areas such as packaging technology, material compatibility, tooling requirements and the best configuration to support efficiency now and scalability over time.

Manufacturing

With the design confirmed, your machine or packaging line moves into production. Equipment is built with a focus on reliability, repeatability and long-term use in demanding production environments. Quality is built into the process from the start, ensuring your solution is engineered to deliver consistent results throughout its working life.

Testing

Before installation, we complete thorough testing to ensure the machine performs as expected and the hardware and software work together correctly. This stage helps confirm everything is running as planned, giving you reassurance before delivery. Customers are also welcome to visit and see their machine in action during testing.

Installation

Our technicians manage installation on site and support the final setup to ensure your equipment is production-ready. We also provide training for your team, helping your team feel confident using the machinery safely and effectively. The goal is a smooth transition into live production, with minimal disruption.

Aftercare Services

Once your line is up and running, we help you protect performance over time. This can include agreed servicing routines, access to technical support when you need it and a quick route to the right spare parts. The aim is to keep production stable, reduce unplanned stoppages and support you as requirements change.

Support That Stays with You

Aftercare Services

Your packaging line is a long-term investment, so reliable aftercare matters.

After installation, ILPRA UK provides continued support designed to reduce downtime and keep your production running smoothly. This includes technical assistance, remote support where appropriate and spare parts support when needed.

From Start-Ups to Automation

Supporting Businesses of All Sizes

We support businesses at every stage, from early growth brands to high-output manufacturers.

We’ve helped small start-ups begin with their first tray sealing machine, then scale over time into larger, more automated solutions as production demand grows. That means you can invest with confidence knowing your packaging setup can evolve with your operation.

Contact Us

Let’s Improve Your Packaging Process

Whether you want to reduce costs, improve performance or scale up production, our team can help you find the right packaging solution.