In Line

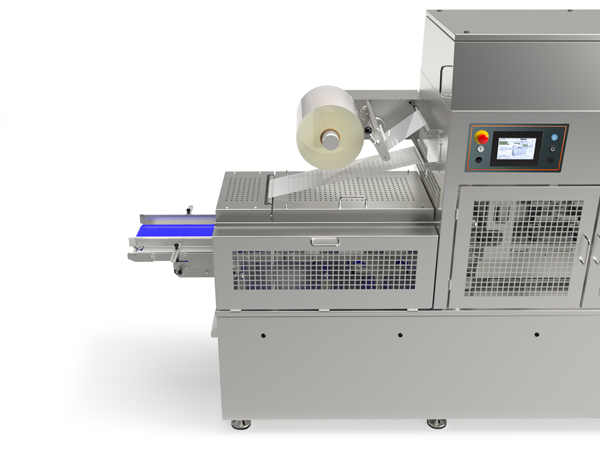

FoodPack 1485

Full Description

The FoodPack 1485 epitomises innovation in automated tray sealing, suited for high-volume production settings. It incorporates CPS technology, ensuring synchronised jaw and belt operation for peak efficiency. Versatile in application, it can handle various packaging needs such as meats, fruits, ready meals, and more.

The machine’s large sealing area, rapid cycle times, and user-friendly design are geared towards optimising space and air usage in busy operations. Additionally, it boasts a robust build, enhancing durability and longevity in demanding production environments. Its intuitive interface simplifies operation, reducing training time and streamlining workflow. The FoodPack 1485’s precision in sealing ensures consistent product quality, reinforcing brand reliability and customer satisfaction.

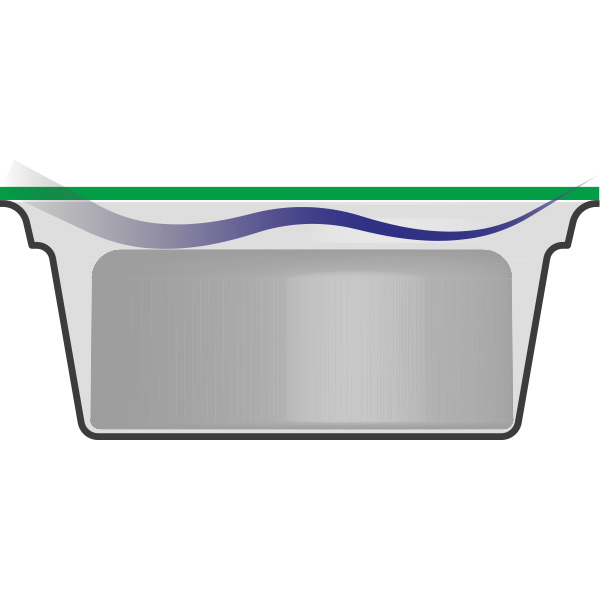

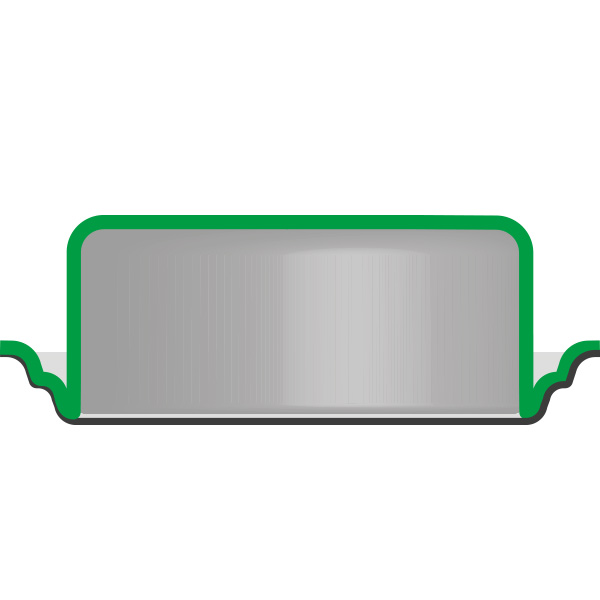

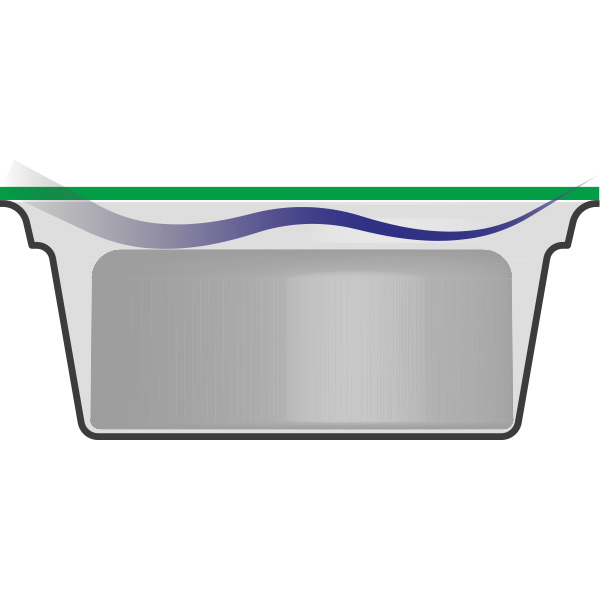

Gas Flush

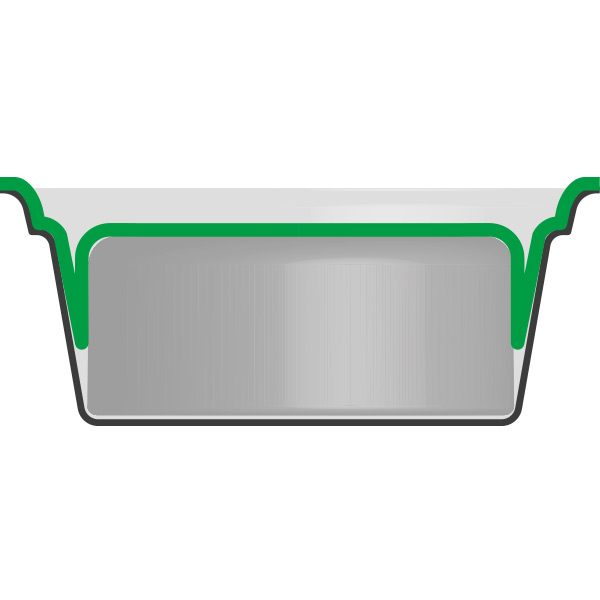

Vacuum

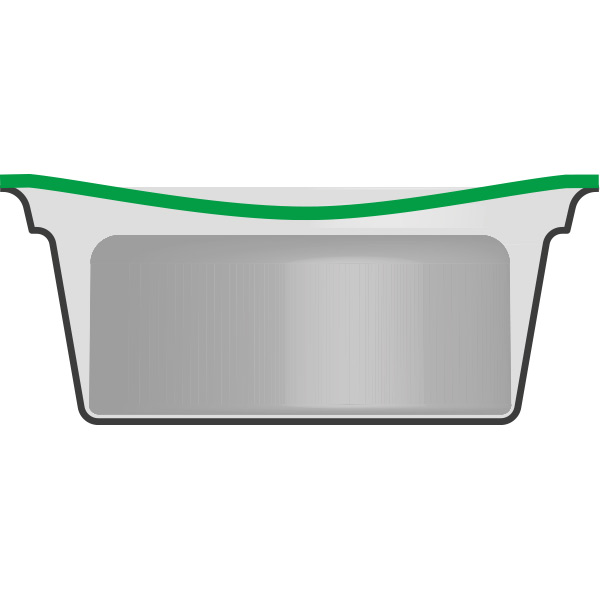

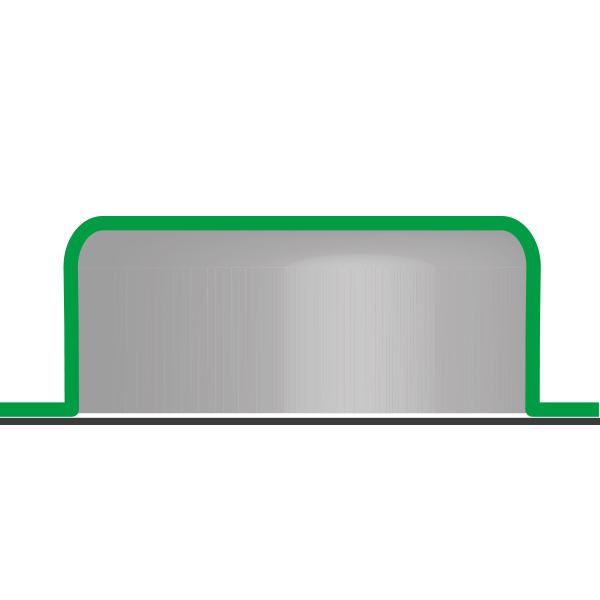

Sealing

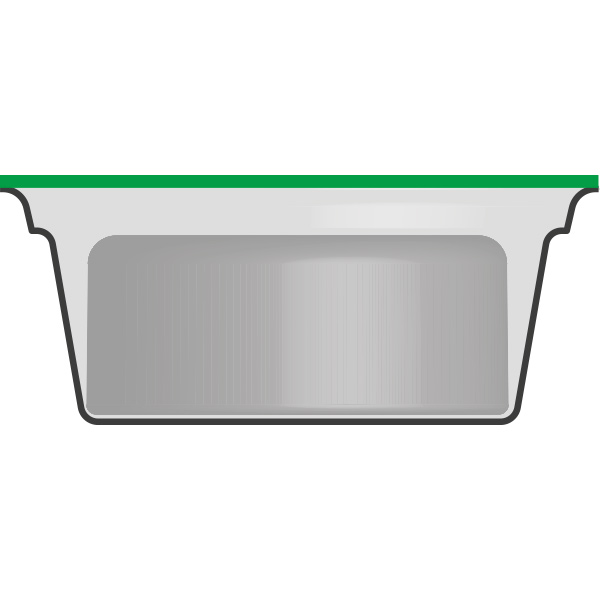

MAP/ATP

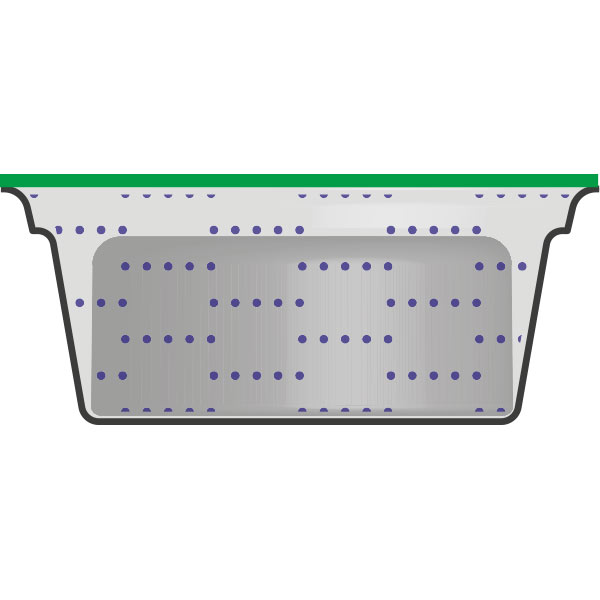

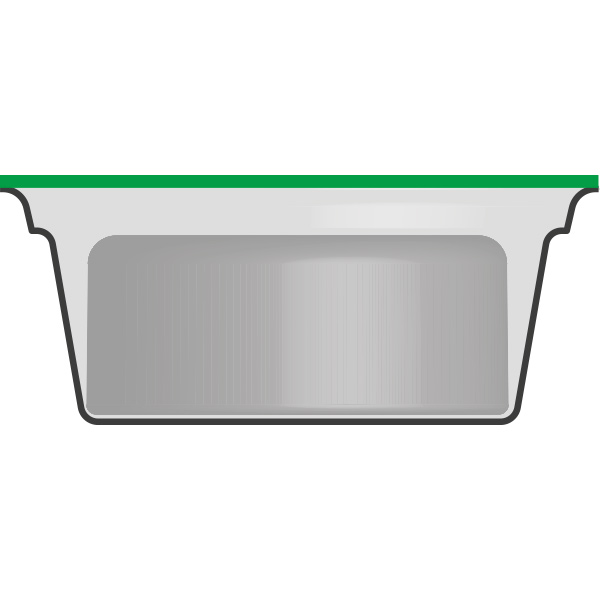

Skin

Overskin

Extraskin

Extraskin on Cardboard

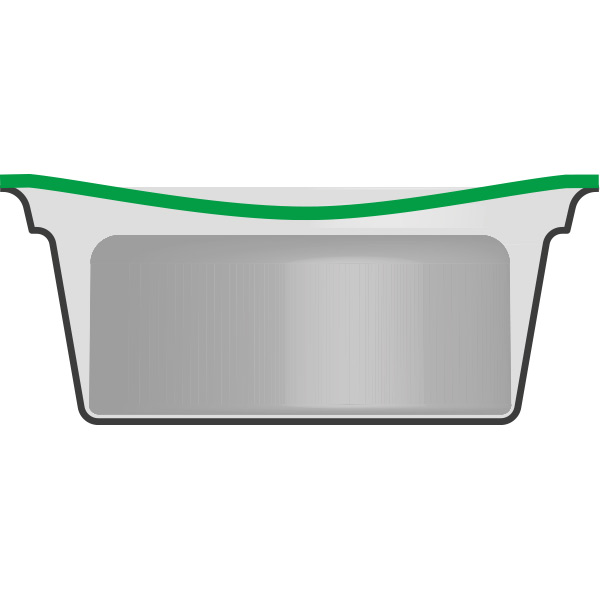

Sealing

Up to 25 cpm

Gas Flush

Up to 22 cpm

MAP/ATP

Up to 15 cpm

Vacuum

Up to 22 cpm

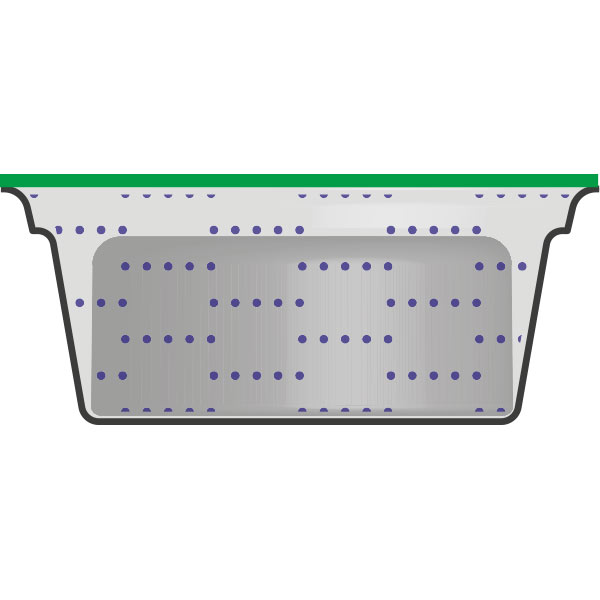

Skin

Up to 8 cpm

Overskin

Up to 7 cpm

Extraskin

Up to 6 cpm

Extraskin on cardboard

Up to 6 cpm

Technical Data

Technical Data : FoodPack 1485

Dimensions: 375 x 90 x h 196 cm

Weight: approx. 1700 Kg

Air Consumption: 6 bar - 5 Nlt/cycle

Sealing Area: 850 x 350 x h 120 mm

Videos

Technology

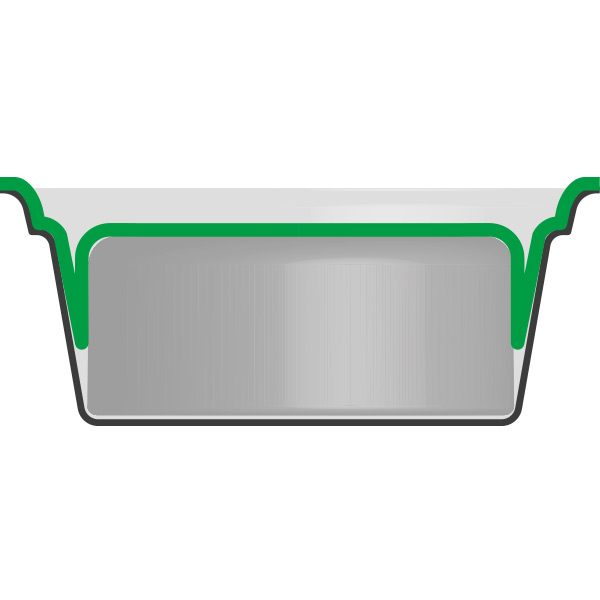

E-MEC Technology

Enhances speed and productivity with electromechanical movement.

PROGAS System

Patented technology reducing gas use and increasing speed.

Constant Placement System

Improves tray inflow and production speed.

Optional: ID Control System

Personnel recognition with badge system.

Optional: ExtraSkin System

Allows high-protrusion skin packaging.

Optional: Pre-Heating System

Optimises packaging by pre-heating the film.

Optional: Predictive Maintenance System

Plans component overhaul and replacement.

Optional: Anti-Crush System

Checks tray positioning to prevent sealing errors.

DETAILS

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.