Dry

Dry Goods & Snacks Packaging

Our machines are built to handle snack packets, powders, resealable tubs and granular products with consistent dosing, hygienic handling and minimal maintenance.

Mono-Material Packaging

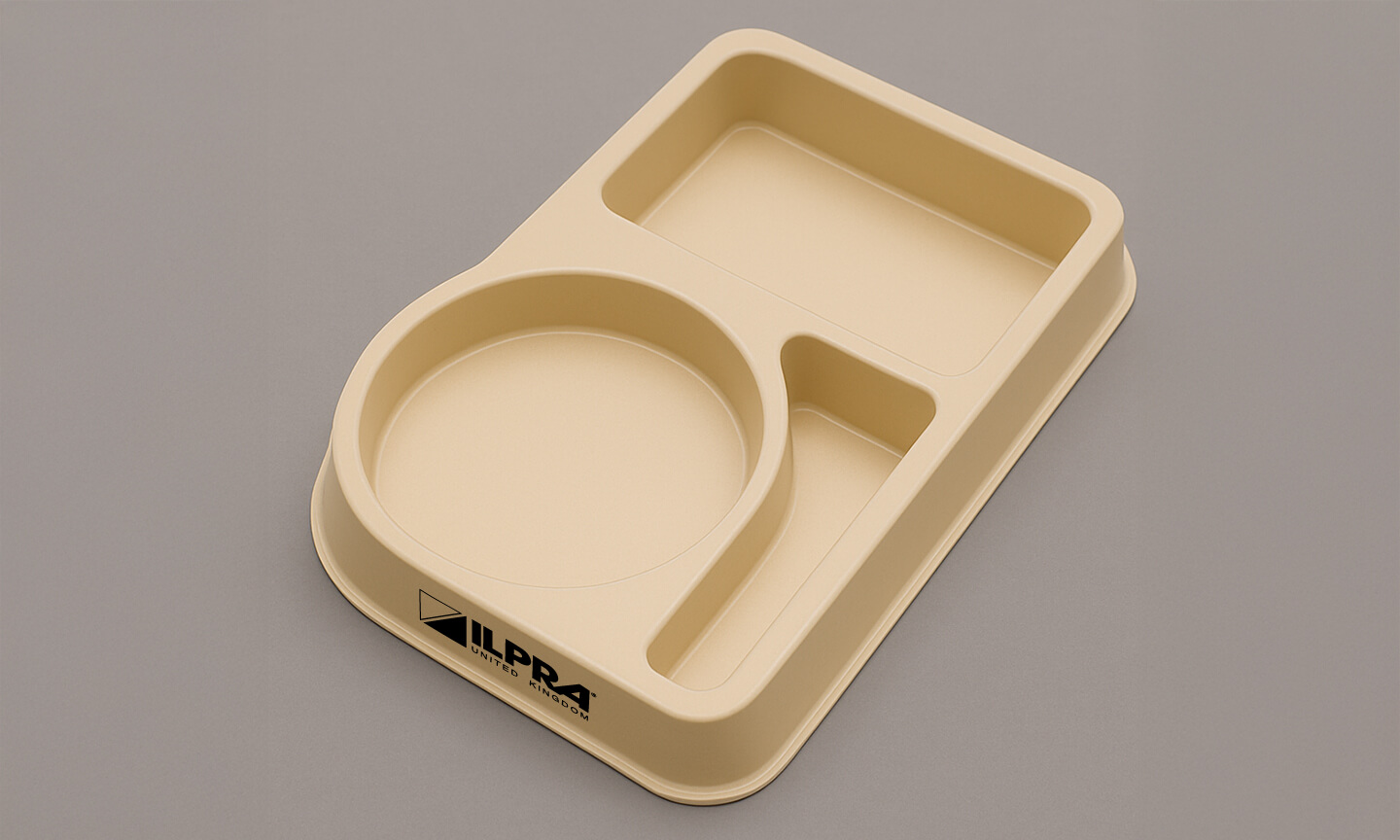

Industry Standard Trays

Film Laminates

Cardboard Skin Trays

Cardboard Trays

Stick Pack Film

Sachet Film Rolls

Thermoforming Film

Rigid Films

Paper Pots

Cotton Net Film

Plastic Pots

Precut Lids

Self-Ventilating Film

Compostable Film

Compostable Trays

Sugar Cane Tray Packaging

Paper Shape Trays

Paper Tray Packaging

Skin Pack Trays

Barrier Trays

Barrier Films

Flow Wrap Film

Premade Pouches

Shrink Wrap Rolls

Aluminium Trays & Pots

Aluminium Film Roll & Pre-cut Lids

Sandwich Packaging Boxes

Custom Packaging Trays

Plastic Bucket Packaging

Polystyrene Trays

Wooden Packaging Trays

HDPE Packaging

Labels for Packaging

Packaging Machines

Dry Goods & Powders Packaging Machines

We specialise in rotary fill-seal machines with 8 or 12 station configurations, specifically designed for packaging dry and free-flowing products in preformed containers.

View all available productsFAQs

Frequently asked questions

Are your machines suitable for powders and dry goods?

Yes. Our rotary fill-seal machines are designed specifically for powders, granules and dry ingredients. These compact systems work with preformed cups, tubs, jars and similar containers. They’re space-saving, simple to operate and built with quick-change tooling so you can switch formats or pack sizes with minimal effort.

Can you customise the dosing system to match my product?

Absolutely. We’ll integrate the dosing system that best suits your product’s consistency and weight range. That includes auger screw fillers for fine powders like flour or supplements, multi-head weighers for granular blends, drawer or volumetric dosers for coarse ingredients and linear weighers for lightweight or delicate items. Every setup is tailored to your product’s flow behaviour and packaging format.

Do you support recyclable or compostable packaging materials?

Yes, we do. Our machines are compatible with recyclable plastic jars, mono-material pots and cardboard-based tubs. We also offer sealing systems that work with pre-cut film and recyclable aluminium lids. We’ll help you test your chosen packaging materials to make sure they meet your functional and regulatory needs while supporting your sustainability goals.

How are your machines adapted for dry product environments?

We configure every machine with the unique requirements of dry goods in mind. That includes dust control features, antistatic handling, accurate weighing and clean filling to reduce mess and airborne particles. If your facility has allergen control or cleanroom protocols, we’ll tailor the system to comply with those too.

Can I automate more than just filling and sealing?

Yes. Alongside filling and sealing, we can integrate container denesting, lid application and labelling systems. This allows you to streamline your production line and reduce manual handling from start to finish. We’ll advise on the best configuration based on your current setup and future plans.

What kind of support do you offer after installation?

We provide full UK-based support including machine installation, operator training and ongoing technical help. Our team is available for routine servicing and troubleshooting, and we keep spare parts in stock to minimise downtime. You can also carry out product testing at our UK site before committing to a full setup.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.