Film-Made

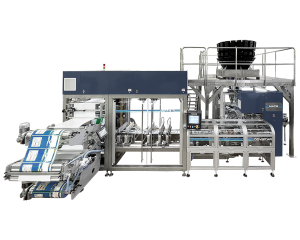

Doystar

Full Description

The Doystar is an advanced packaging solution that creates pouches directly from film. It incorporates servo-driven control and rotary die-cutting for precision and efficiency. The machine’s design includes horizontal film unwinding, active film tension control, and a rotary turret with six operational positions, ensuring smooth and consistent performance.

This machine is uniquely adaptable, with five different operating scales built into one machine.

- Simplex: One lane, producing one pouch at a time.

- Duplex: Two lanes, producing two pouches at a time.

- Triplex: Three lanes, producing three pouches at a time.

- Quadruplex: Four lanes, producing four pouches at a time.

- Quintuplex: Five lanes, producing five pouches at a time.

This multi-lane capability increases the machine’s output, enabling higher production speeds and greater efficiency.

The open-frame design allows 360° accessibility, making maintenance and cleaning straightforward. It also features a buffer system between forming and filling sections, enhancing overall efficiency. Capable of converting from Simplex to Quintuplex within 30 minutes, this machine is both versatile and adaptable.

Technical Data

- Model: Doystar

- Reel Max. Diameter: ø 600 mm

- Reel Core Diameter: ø 76/152 mm

- Min/Max Pouch Width:

- Simplex: 80/505 mm

- Duplex: 60/250 mm

- Triplex: 50/160 mm

- Quadruplex: 50/90 mm

- Min/Max Pouch Height: 130/340 mm

- Min/Max Pouch Gusseting Height: 15/60 mm

- Target Speed Up to 500g: 240 ppm

- Target Speed Up to 1000g: 160 ppm

- Noise: < 80 dB

- Electrical Consumption: 400/480 VAC, 50/60 Hz

- Pneumatic Consumption: 6 bar – 1100 Nl/min

Videos

Technology

Innovative Motion Features

The machine is entirely servo-commanded for precise control and high efficiency.

Rotary Servo-Driven Cutting Drum

The punching die-cut system uses a rotary servo-driven cutting drum for accuracy.

Horizontal Film Unwinding

The film is unwound horizontally, similar to a converting machine.

Active Film Tension Control

Controlled through loading cells for consistent tension.

Rotary Turret

Features six operational positions for versatile pouch handling.

Additional Options

- Zipper inserting system

- Inert gas flushing unit (MAP)

- Second reel holder

- Automatic reel splicing unit

- Pouch top edges trimming unit

- Corner spout applicator

- Top spout applicator

- Filling through spout machine version with screwing tap system

- Additional feeding station for multiple products in one pouch

- Automatic format changeover with servo positioners (15 minutes)

- Adjustable bottom and side sealers from HMI without mechanical intervention

- Volumetric filling by hygienic design piston filler

- Mass flowmeters and plunging nozzles

- Multi-head weigher integration with various brands

- Round corners shaping unit

- Total shape die cut unit

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.