Rotative

Fill Seal 2000

Full Description

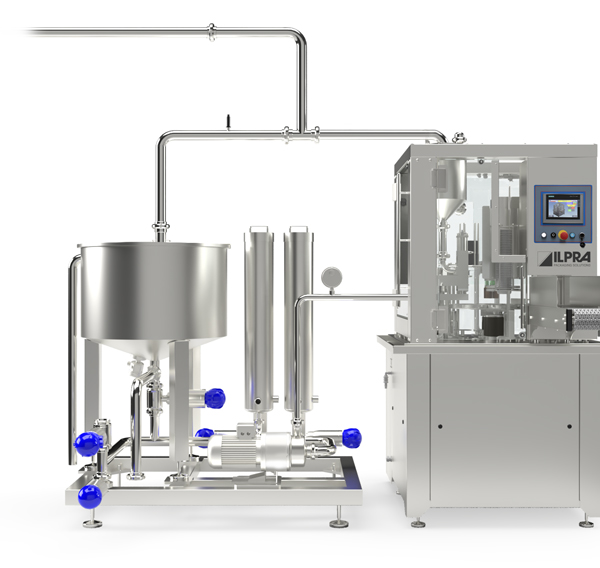

The Fill Seal 2000 stands as the introductory model within the Fill Seal line, offering an ultra-compact design ideal for businesses looking to efficiently package dairy products, yoghurt, condiments, sauces, and more.

This rotary table machine is engineered for simplicity and efficiency, accommodating one jar per station and boasting a maximum output of 2,000 pieces per hour. Its user-friendly touch screen panel allows for easy setting of work parameters and stores multiple recipes for quick access, ensuring a seamless operation.

The machine is equipped with a volumetric doser for precise filling of a wide range of products, from liquids to granular substances, and features options for Clean in Place (CIP) technology, ensuring thorough and efficient cleaning. With additional accessories like the pick & place device, suction for foreign materials, various dosing systems, a crimping system for glass or ceramic pots, and an inkjet printer for adding essential product information, the Fill Seal 2000 is a versatile solution tailored to meet the needs of small to medium production volumes, prioritising hygiene, accuracy, and operational efficiency.

- Sealing -

Sealing

Up to 35 cpm

Sealing Fill

Up to 35 cpm

Technical Data

Technical data : Fill Seal 2000

Dimensions : 166 x 101 x h 188 cm

Weight: Approx. 550 Kg

Installed electric power : 2,5 Kw

Pots per cycle : 1

Ø Max Pots Lid : 125 mm

Max Pots Height : 130 mm

Videos

Single Dose Packaging Mayonnaise

Technology

Pick & Place

The Pick & Place accessory automates the placement of pre-filled containers into the machine, streamlining the packaging process and enhancing efficiency.

Suction of Foreign Materials

This feature uses an air jet to lift and remove any external materials from the bottom of the container, ensuring product purity and safety.

Dosing Systems

ILPRA offers a variety of dosing systems, including volumetric, timed, drawer, and flowmeter options, to ensure fast and precise filling for a range of products.

Crimping System

Installed on the exit belt, the Crimping System securely attaches lids to the edges of glass or ceramic pots, enhancing seal integrity and product safety.

Inkjet

The Inkjet printer adds essential information like expiration dates and production lots to packaging, providing a complete solution for product identification and traceability.

DETAILS

End of Line Add-Ons

Browse Compatible Machines

From palletizers to labellers, finalise your production line with automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.