In Line

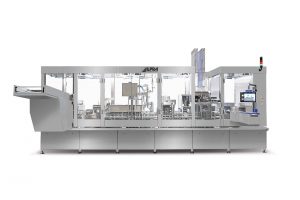

Fill Seal In-line

Full Description

The Fill Seal In-line machines are a robust solution for enhancing operational efficiency and product quality within the manufacturing sector.

Designed with scalability and adaptability in mind, these machines cater to a wide range of packaging needs and production volumes, making them an ideal choice for businesses aiming to increase their output without compromising on quality. Their modular design not only allows for easy integration of various accessories but also ensures that the system can evolve alongside your business needs, offering both production and sanitisation capabilities that are crucial for maintaining high standards of product integrity and safety.

Incorporating features such as Modified Atmosphere Packaging (MAP), vacuum sealing, and gas flush, the Fill Seal In-line machines significantly extend the shelf life of products, ensuring they remain fresh and appealing to consumers for longer. The inclusion of advanced sanitisation technologies, like UVC lamps and hydrogen peroxide atomisation, guarantees that hygiene standards are consistently met, providing peace of mind in the fast-paced manufacturing environment. With their focus on optimising productivity and improving product handling, these machines represent a forward-thinking investment for businesses looking to streamline their packaging processes and enhance overall efficiency.

- Sealing -

- Gas Flush -

- Vacuum -

- MAP/ATP -

Technical Data

Product: Yogurt

Cup Material: Paper & PP

Cup Volume: 100 cc

Cup Diameter: Ø 75 mm

Cup Shape: Round

Lid Material: Aluminium

Productivity: Up to 24,000 cups/hour

Videos

6L Set Yogurt Packaging

5L Sauce Packaging with Gas Flush

4L Milk Container Fill and Seal

Technology

High-Capacity Storage

Equipped with an automatic infeed conveyor and ample storage capacity, this feature ensures unparalleled autonomy for both the machinery and its operators, streamlining the production process and reducing the need for constant manual intervention.

Cups Sanification

Utilising UVC lamps, pulsed light, or hydrogen peroxide atomisation, this station offers a robust solution for sanitising cups, ensuring the highest standards of hygiene and safety for the packaged products.

Dosing System

At the core of the machine, the dosing system is meticulously designed to cater to the specific needs of the customer and the type of product being packaged, ensuring precise and consistent product filling.

Lids Denester

This component efficiently handles pre-cut lids, placing them accurately on the pots. Its design focuses on maximising operational autonomy, streamlining the packaging process.

Precut Lids Sanification

Featuring UVC or pulsed light lamps, this station is dedicated to sanitising precut lids, significantly reducing any bacterial load and ensuring product safety and longevity.

Sealing Station

Specialising in the sealing of lids or films onto pots, this station’s high efficiency plays a crucial role in extending the shelf life of the product, maintaining its quality and freshness.

Lids Storage

Designed to enhance operational efficiency, this station stores lids and places them on containers as needed, boasting a high capacity that supports sustained autonomy in production.

Cups Ejection

Ensuring an orderly and consistent ejection of pots onto a fully washable belt, this station facilitates smooth transitions to secondary packaging systems, enhancing the overall packaging line efficiency.

Tray-Carrier Cleaning and Drying

This automatic washing system is dedicated to the cleaning and drying of tray-carriers, maintaining the cleanliness and readiness of the machinery for continuous operation.

DETAILS

End of Line Add-Ons

Browse Compatible Machines

From palletizers to labellers, finalise your production line with automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.