In Line

FoodPack 1440

Full Description

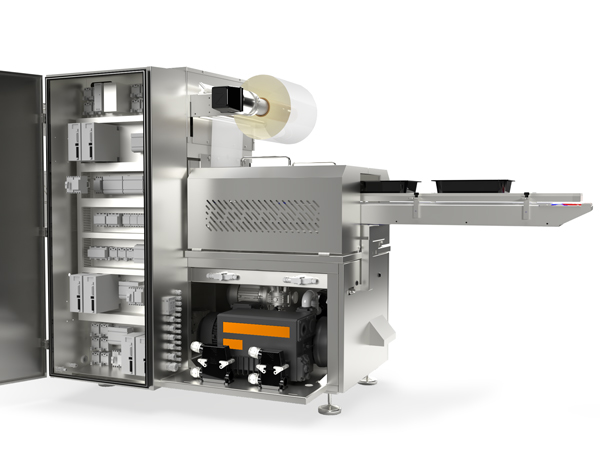

The FoodPack 1440 is an ultra-compact, automatic in-line tray sealer that represents an ideal entry-level solution for businesses looking to enhance their packaging operations.

Designed to seamlessly integrate into existing production lines, this machine excels in packaging a variety of products such as ready meals, pasta, and meats, thanks to its large sealing area and ease of use. Its compact dimensions and efficient air consumption make it a practical choice for operations where space and efficiency are at a premium.

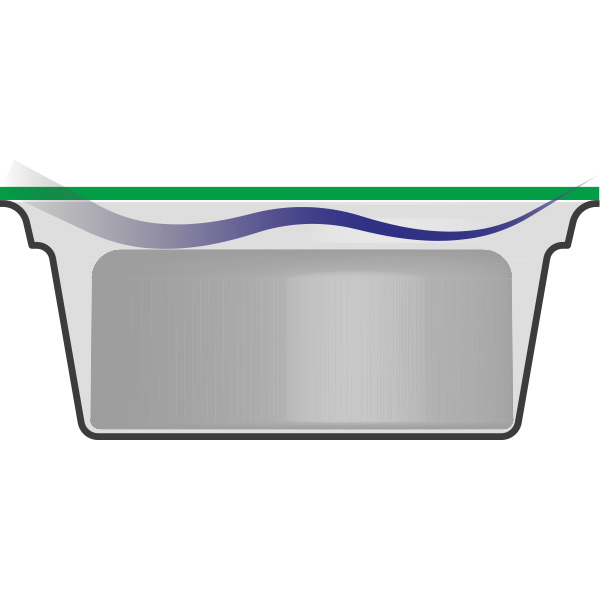

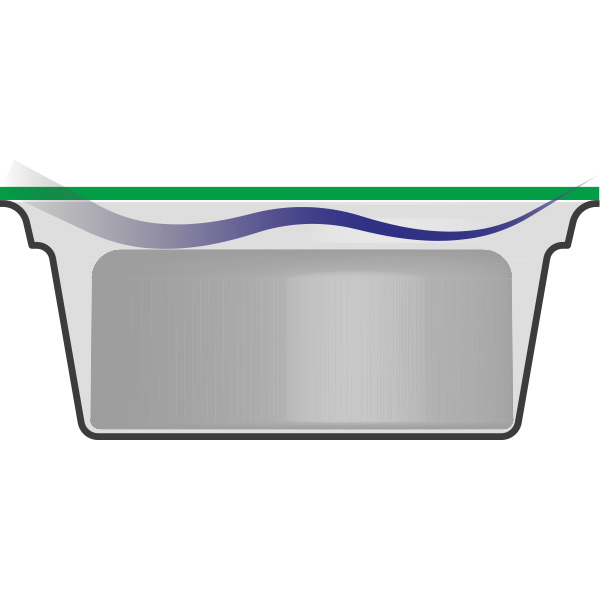

Gas Flush

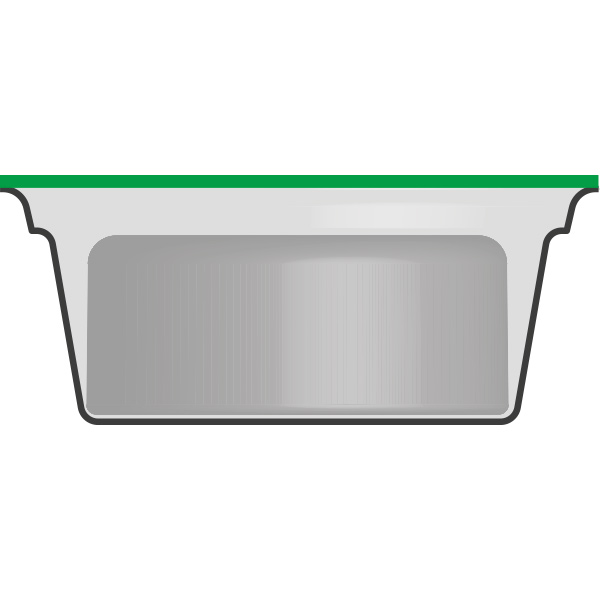

Vacuum

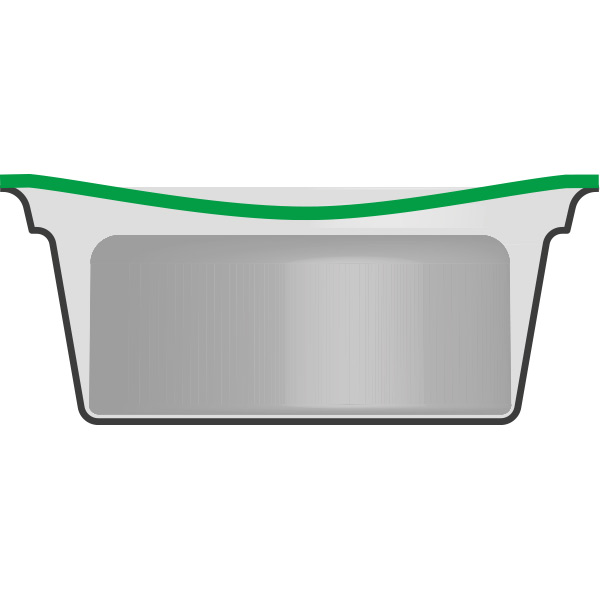

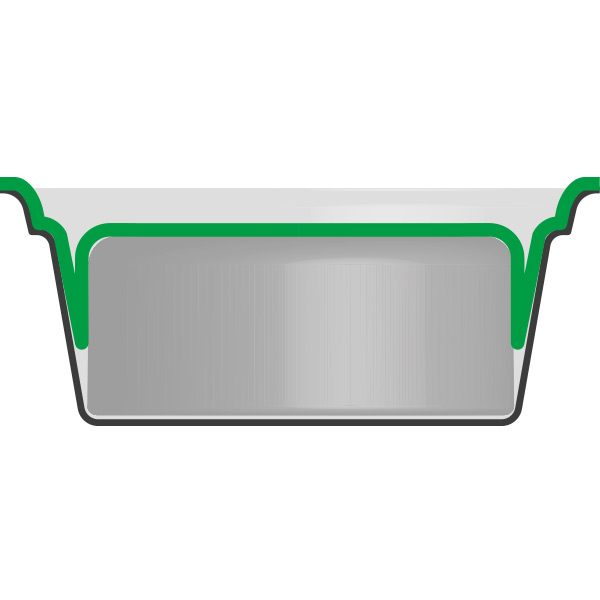

Sealing

MAP/ATP

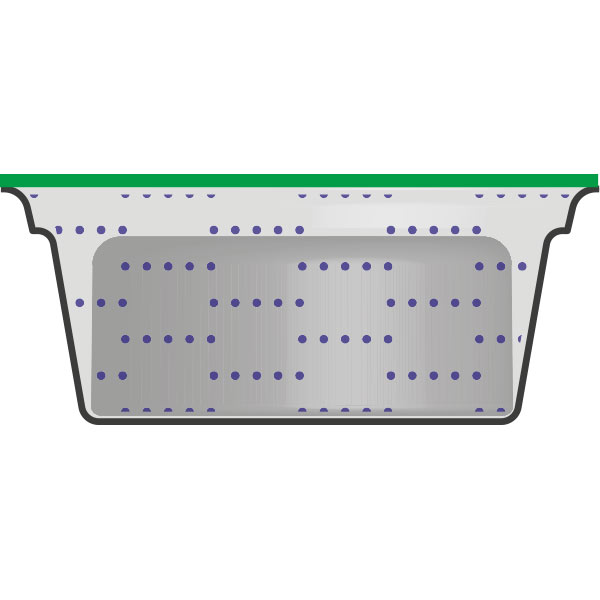

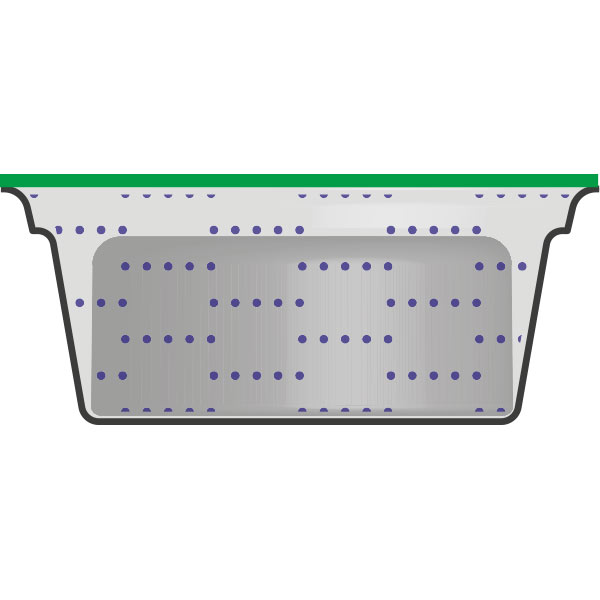

Skin

Overskin

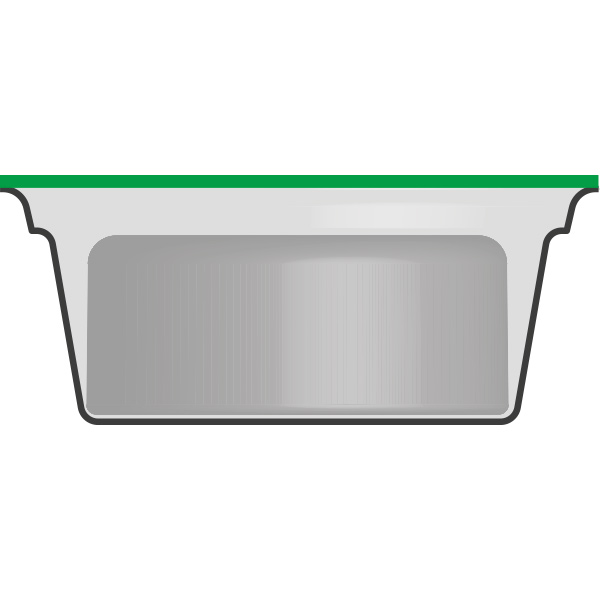

Sealing

up to 22 cpm

Gas Flush

up to 20 cpm

MAP/ATP

up to 15 cpm

Vacuum

up to 22 cpm

Skin

up to 8 cpm

Overskin

up to 7 cpm

Technical Data

Technical Data : FoodPack 1440

Dimensions: 309 x 105 x h 154 cm

Weight: 1000 Kg

Air Consumption: 6 - 9 (N) / 12 (VG) Nlt/Cycle

Sealing Area: 400 x 270 x h 120 mm

Videos

Dessert Compact Tray Sealer

Sauces Tray Sealer with Walking Beam

In-line Tray Sealer with Chain Motion

Russian Salad In-Line Tray Sealer

Technology

E-MEC Technology

Utilises a fully electromechanical movement within the workstation, enhancing both the speed and productivity of the packaging process.

PROGAS System

A patented technology by ILPRA, designed to reduce gas consumption while increasing operational speed. This system is a standard feature across the entire product range.

Optional Pre-Heating System

Offers the capability to pre-heat the sealing film, optimising the packaging process for skin-packed products.

DETAILS

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.