In Line

FoodPack 1465

Full Description

This machine is engineered to integrate effortlessly into existing setups, offering high mould yield and swift cycle times for enhanced efficiency.

Equipped with standard CPS (Constant Placement System) technology, the FoodPack 1465 excels in optimizing production through advanced jaw and belt synchronization. Its flexible design allows for customization to suit a broad spectrum of packaging needs, including poultry, snacks, meat, ready meals, fish, and fresh produce.

Designed for high efficiency and seamless integration, the FoodPack 1465 is an automatic in-line tray sealer that sets new standards in packaging technology. It is ideal for businesses seeking to boost their production capabilities, accommodating an extensive range of products with its large sealing area and user-friendly features. The machine’s dimensions and air consumption are optimized for high-volume operations, making it a prime choice for industries aiming to maximize space and productivity.

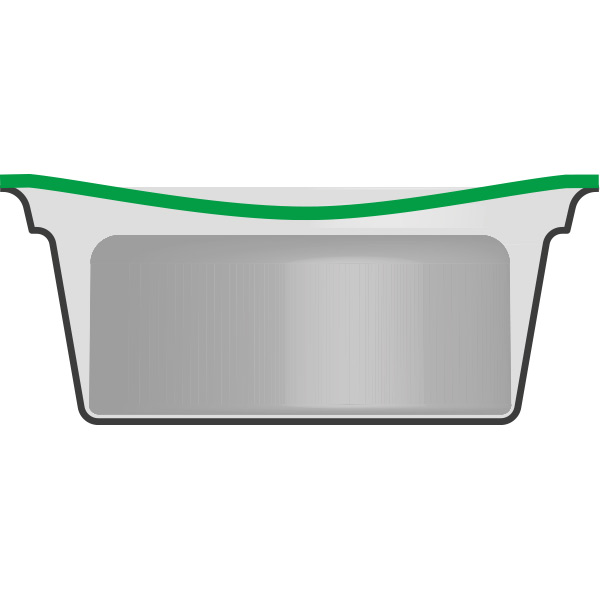

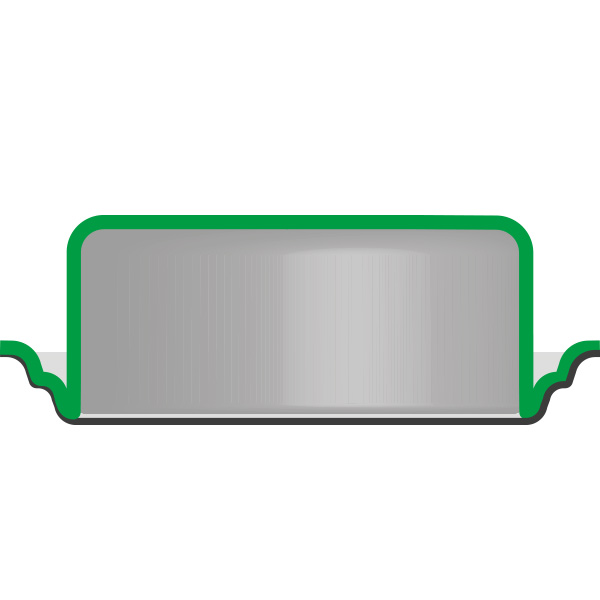

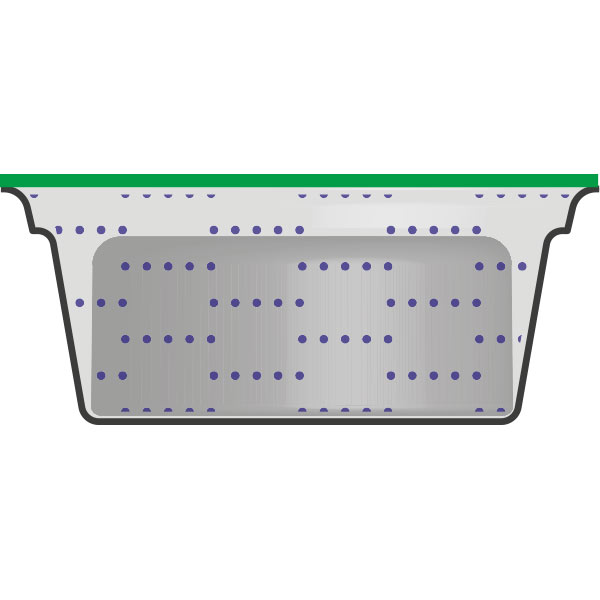

Gas Flush

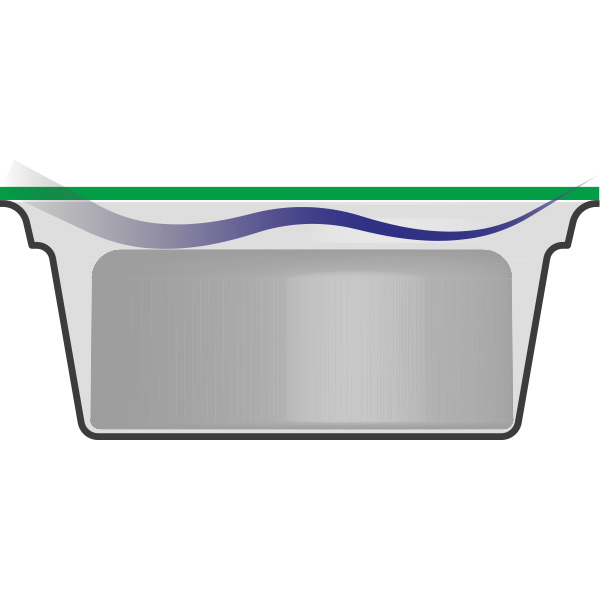

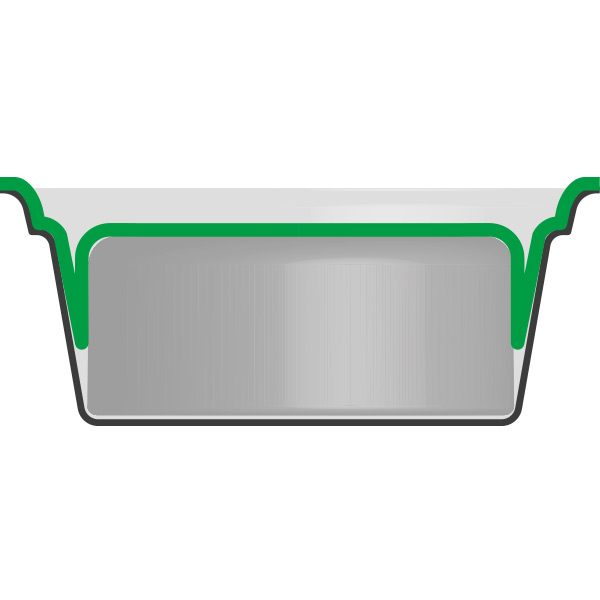

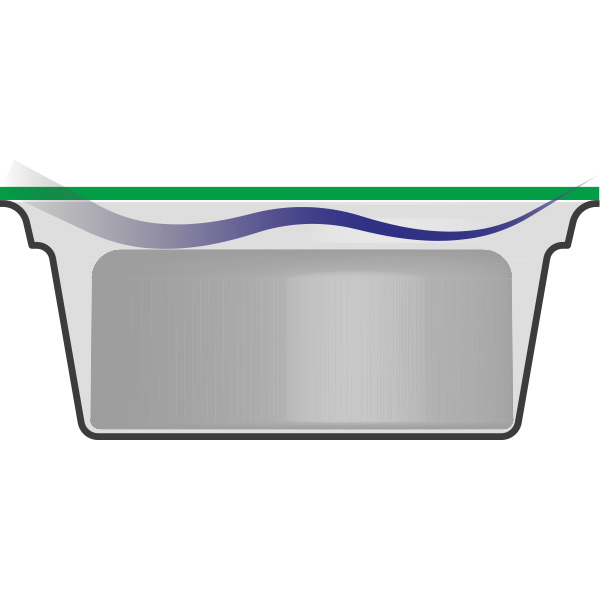

Vacuum

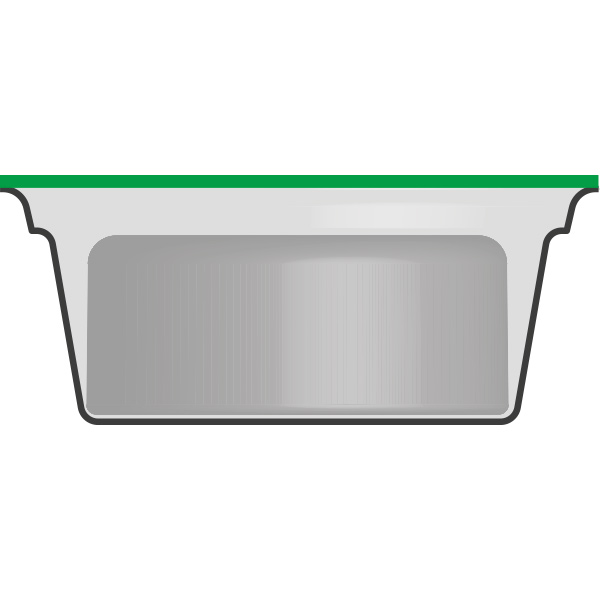

Sealing

MAP/ATP

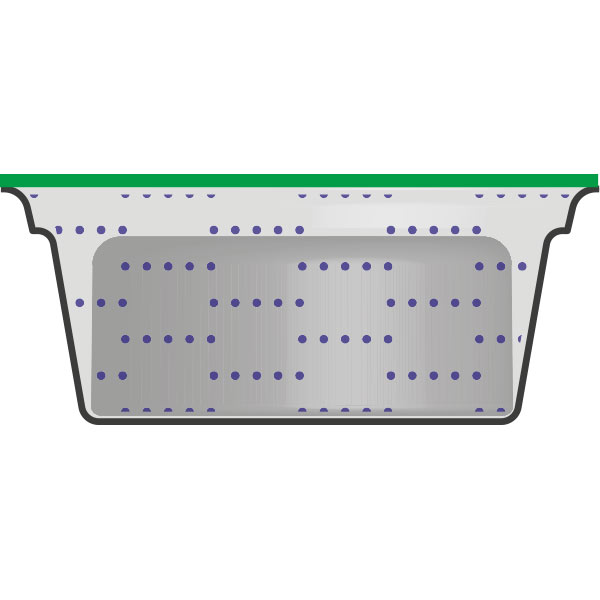

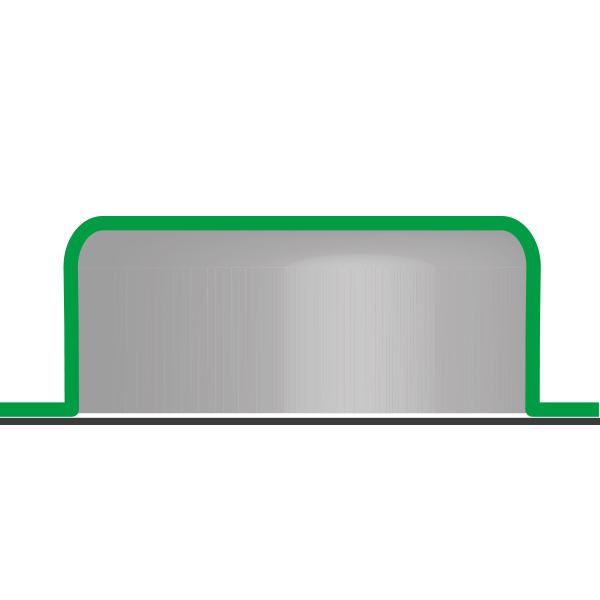

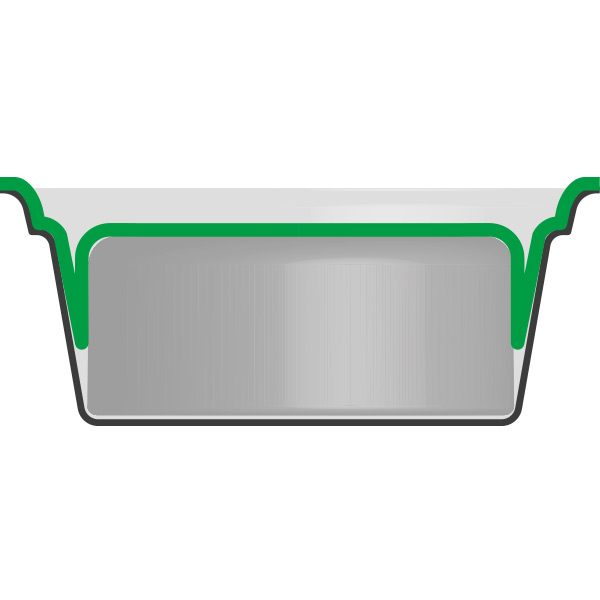

Skin

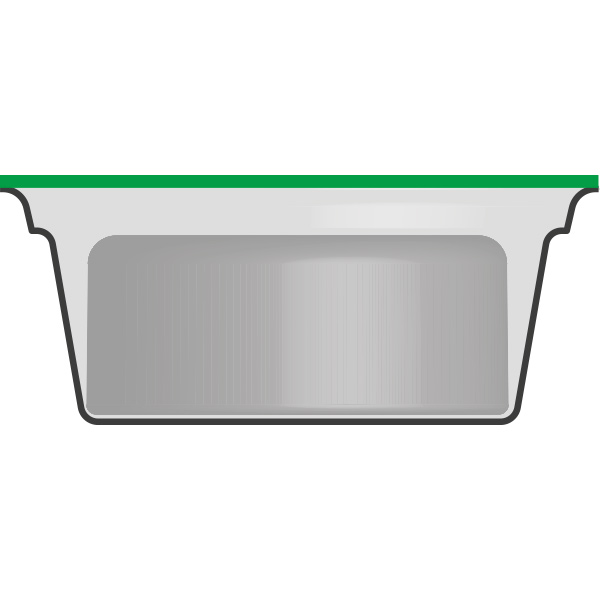

Overskin

Extraskin

Extraskin on Cardboard

Sealing

Up to 25 cpm

Gas Flush

Up to 22 cpm

MAP/ATP

Up to 15 cpm

Vacuum

Up to 22 cpm

Skin

Up to 8 cpm

Overskin

Up to 7 cpm

Extraskin

Up to 6 cpm

Extraskin on cardboard

Up to 6 cpm

Technical Data

Technical Data : FoodPack 1465

Dimensions: 342 x 90 x h 190 cm

Weight: 1350 Kg

Air Consumption: 6 bar - 5 Nlt/cycle

Sealing Area: 680 x 350 x h 120 mm

Videos

Technology

E-MEC Technology

Employs fully electromechanical movements for enhanced speed and productivity, streamlining operations.

ProGas System

ILPRA’s patented system that minimises gas use while boosting operational speed, available across all models.

Constant Placement System

Innovative technology ensuring uninterrupted tray flow, increasing production speed through precise belt and jaw synchronization.

Optional: ExtraSkin System

Allows for advanced skin packaging, even with significant product protrusion, broadening packaging options.

Optional: Pre-Heating System

Pre-heats film to optimise skin packaging efficiency, ensuring a higher quality seal.

Optional: Predictive

A maintenance system that schedules overhauls and part replacements, enhancing machine uptime.

Optional: ID Control System

Implements badge-based staff authentication, offering multiple levels of access control.

Optional: Anti-Crush System

Automatically detects and corrects tray misalignment, stopping the machine to prevent product damage.

DETAILS

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.