In Line

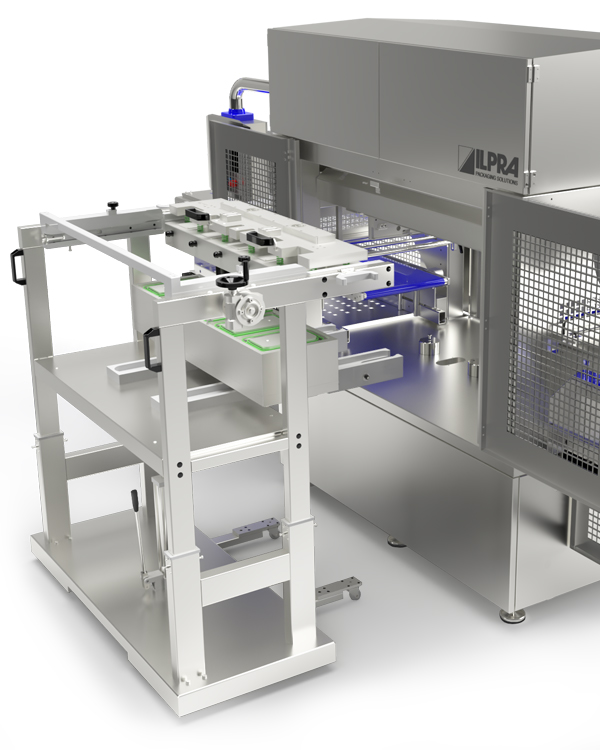

FoodPack Hyper

Full Description

The FoodPack Hyper, available in 1000 and 1250 versions, is tailored for high-speed, large-scale production. It incorporates new CPS technology for continuous infeed of trays, significantly increasing production speed.

The machine features easy integration into production lines and includes an Anti-crush System, an ID Control System for personnel recognition, and Predictive maintenance for component overhaul planning.

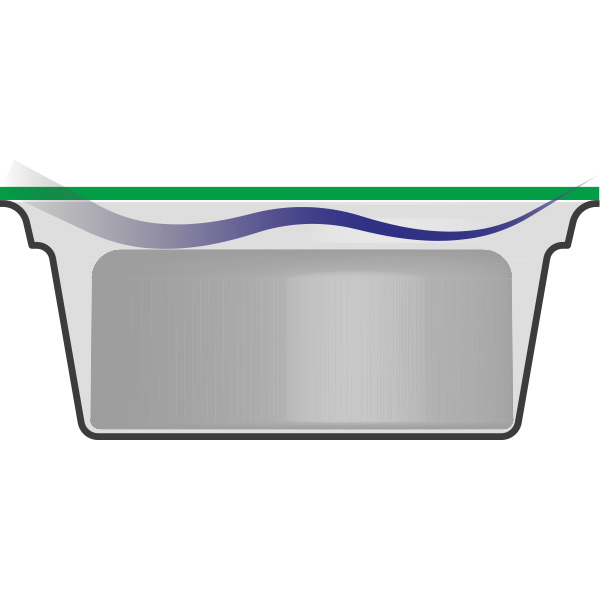

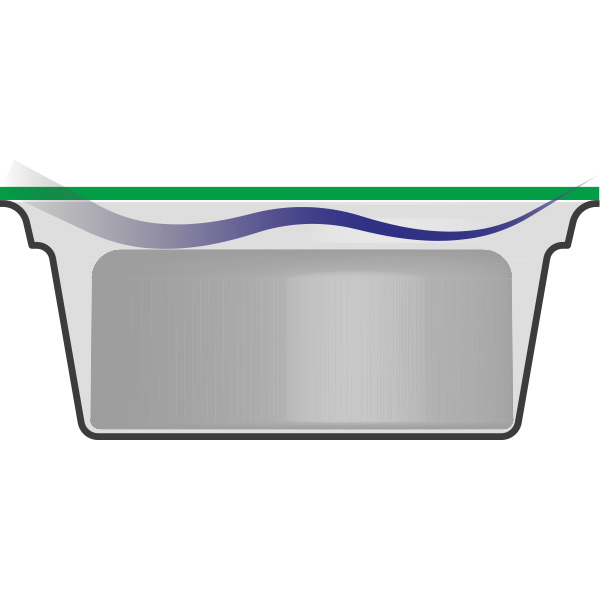

Gas Flush

Vacuum

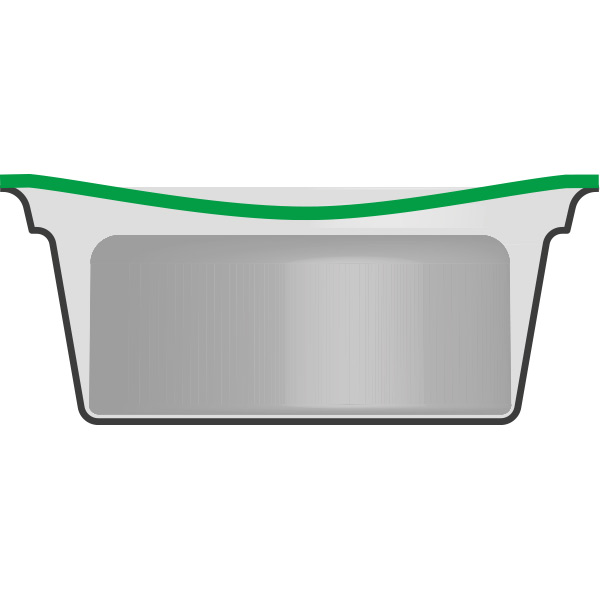

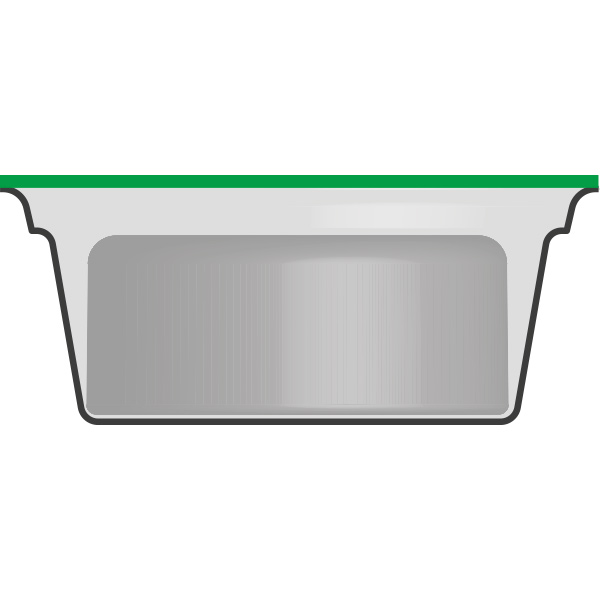

Sealing

MAP/ATP

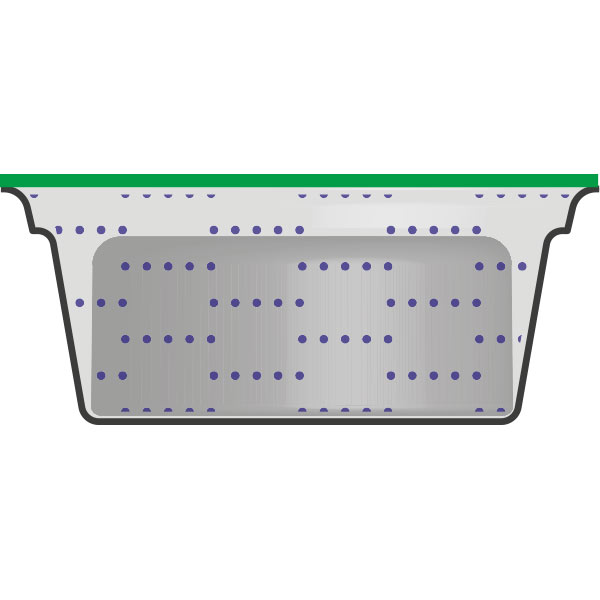

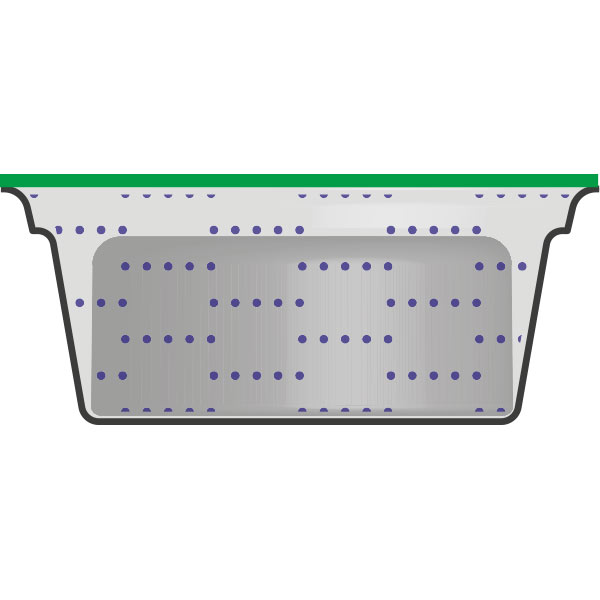

Skin

Overskin

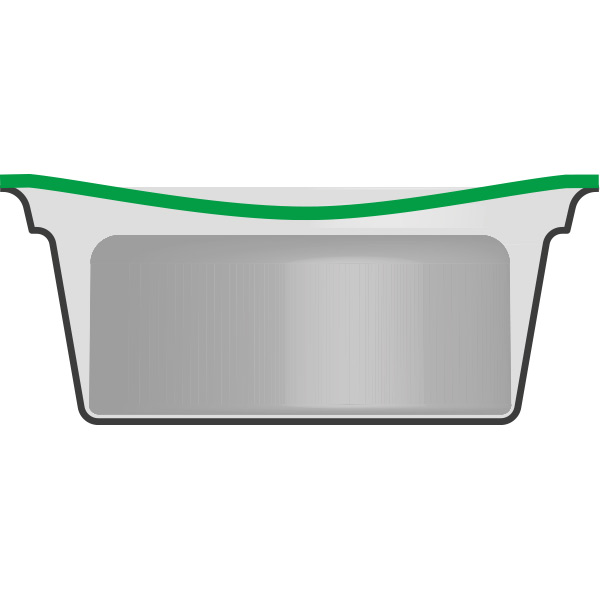

Extraskin on Cardboard

Extraskin

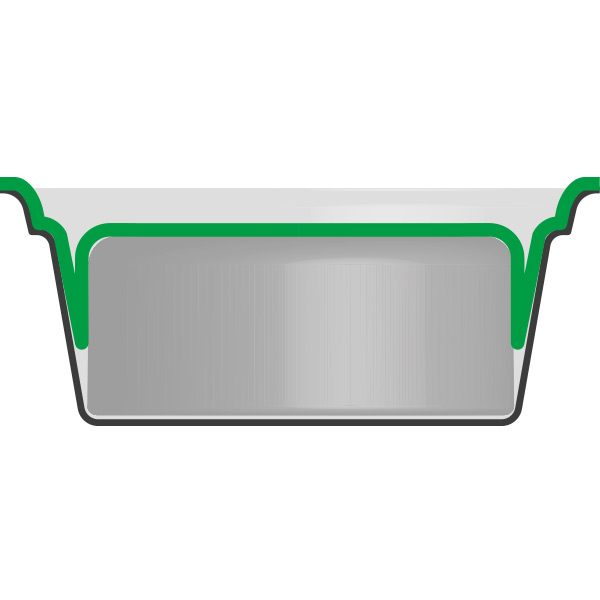

Sealing

up to 25 cpm

Gas Flush

up to 22 cpm

MAP/ATP

up to 15 cpm

Vacuum

up to 22 cpm

Skin

up to 8 cpm

Overskin

up to 7 cpm

Extraskin

up to 6 cpm

Extraskin on cardboard

up to 6 cpm

Technical Data

Technical Data : FoodPack Hyper 1000

Dimensions: 422 x 110 x h 211 cm

Weight: circa 1800 Kg

Air Consumption: 6 bar – 3 Nlt/cycle

Sealing Area: 1000 x 450 x h 120 mm

Technical Data : FoodPack Hyper 1250

Dimensions: 498 x 110 x h 211 cm

Weight: circa 2000 Kg

Air Consumption: 6 bar – 3 Nlt/cycle

Sealing Area: 1250 x 450 x h 120 mm

Videos

Technology

E-MEC Technology

This technology, based on fully electromechanical movements, boosts the speed and productivity of the machine.

PROGAS System

A patented ILPRA technology, the PROGAS System enhances efficiency with reduced gas usage and higher working speeds.

Constant Placement System

It ensures a steady inflow of trays, increasing production speed through precise belt and jaw coordination.

ID Control System

This system involves badge-based recognition of authorised personnel with multiple levels of identification.

Anti-Crush System

This feature checks the correct positioning of trays, stopping operations to prevent errors in case of misalignment.

Predictive Maintenance

A system designed for planning maintenance activities, including component overhaul and replacement.

Optional: ExtraSkin System

This system facilitates Skin packaging, accommodating even high degrees of protrusion, enhancing the versatility and quality of packaging.

Optional: Pre-Heating System

Optimises the skin packaging process by pre-heating the film, leading to a more efficient and agile operation.

Details

End of Line Add-Ons

Browse Compatible Machines

From palletizers to labellers, finalise your production line with automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.