Semi-automatics

FoodPack 400 Extra Roto (SKIN)

Full Description

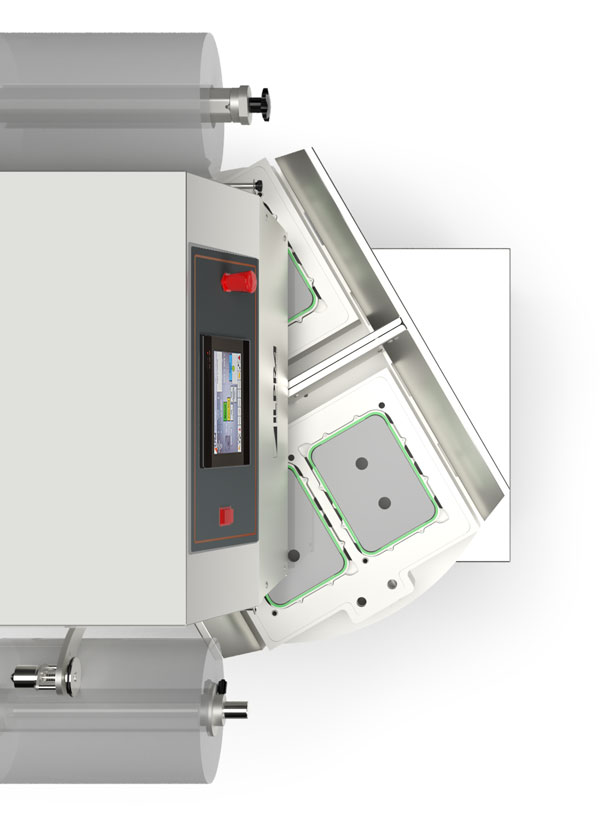

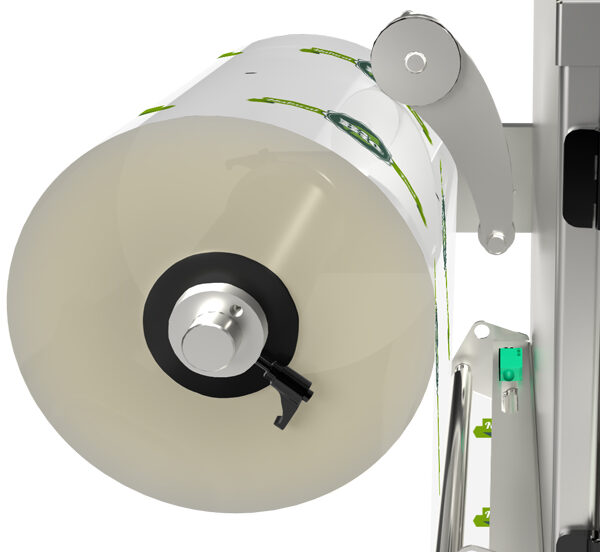

The FoodPack 400 Extra Roto is designed for specialised skin food packaging, particularly excelling in handling high protrusion packaging. Its rotary table feature enhances operational efficiency, allowing simultaneous loading, unloading, and sealing processes.

This makes it an excellent choice for small production settings where efficiency and specialty packaging are priorities with a low investment. The machine’s design and functionality reflect a commitment to meeting specific packaging needs while maintaining user-friendliness and compactness.

Sealing

MAP/ATP

Gas Flush

Skin

Vacuum

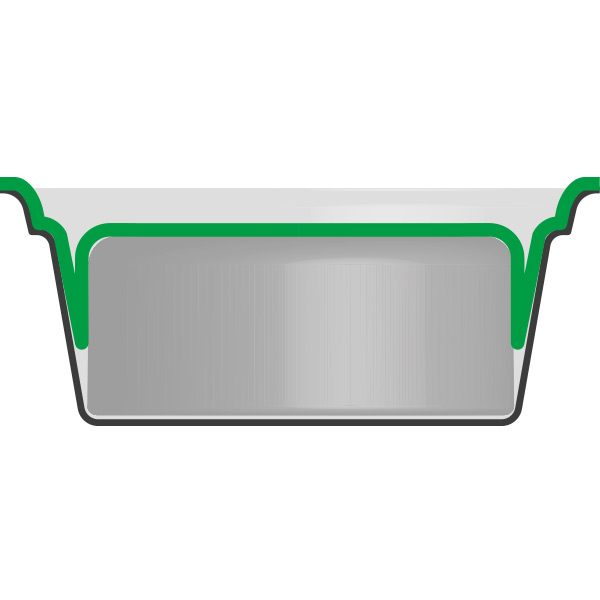

Overskin

Extraskin

Extraskin on Cardboard

Extraskin

fino a 4 cpm

Extraskin on cardboard

fino a 4 cpm

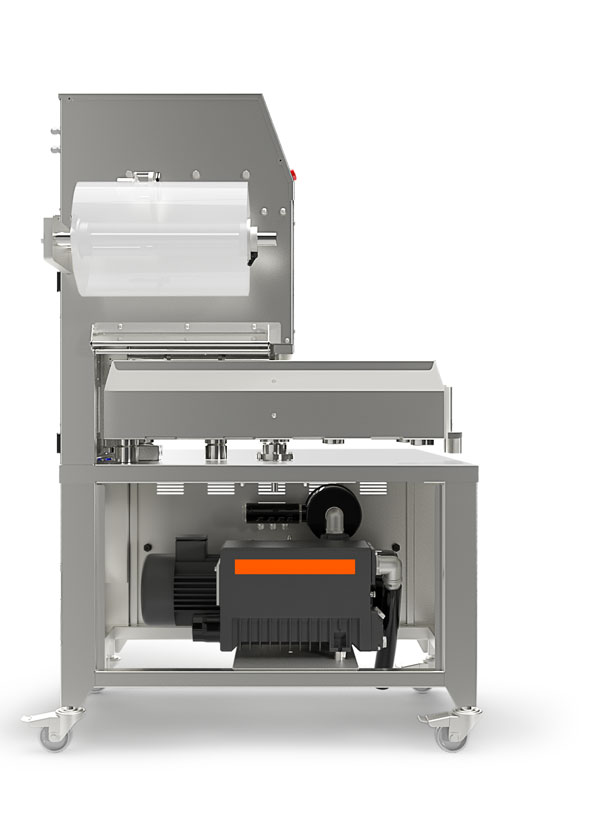

Technical Data

Dati Tecnici : FoodPack 400 Extra Roto

Dimensioni : 124 x 112 x h 160 cm

Peso : circa 330 Kg

Consumo Aria Vacuum Gas: 6 bar - 30 Nlt/cycle

Consumo Aria ExtraSkin : 6 bar - 70 Nlt/cycle

Area di Saldatura Vacuum Gas: 420 x 300 x h 135 mm

Area di Saldatura ExtraSkin : 400 x 300 x protrusione 50 mm ( opzionale 70 mm )

Videos

Technology

PROGAS System

The PROGAS System in the FoodPack 400 Extra Roto is a patented technology that significantly reduces gas consumption while enhancing operational speed.

ExtraSkin

ExtraSkin technology in this machine allows for exceptional skin packaging capabilities. It can handle higher degrees of protrusion, providing versatile packaging solutions.

DETAILS

End of Line Add-Ons

Browse Compatible Machines

From palletizers to labellers, finalise your production line with automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.