Automatics

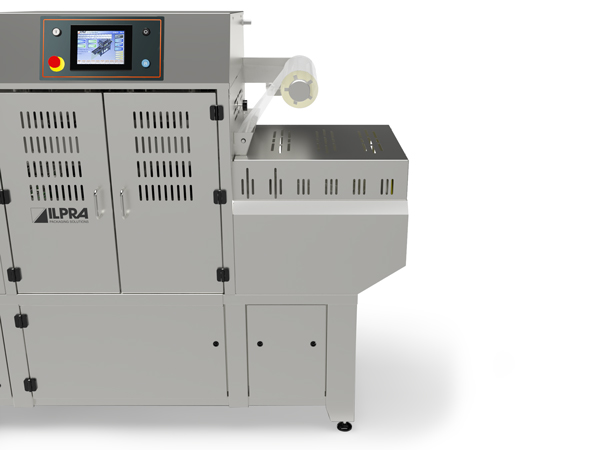

FoodPack Speedy Duo

Full Description

The FoodPack Speedy Duo stands out with its dual independent sealing units, a feature that significantly boosts productivity by allowing simultaneous processing of different product formats. This innovative design streamlines production by minimising the need for mould changes, making it highly efficient for operations requiring versatility.

The machine is adept in various packaging types, including vacuum and MAP, and is equipped with a user-friendly touch screen interface. Its adaptability and efficiency make it a valuable asset in diverse production settings, catering to evolving packaging demands.

Sealing

Gas Flush

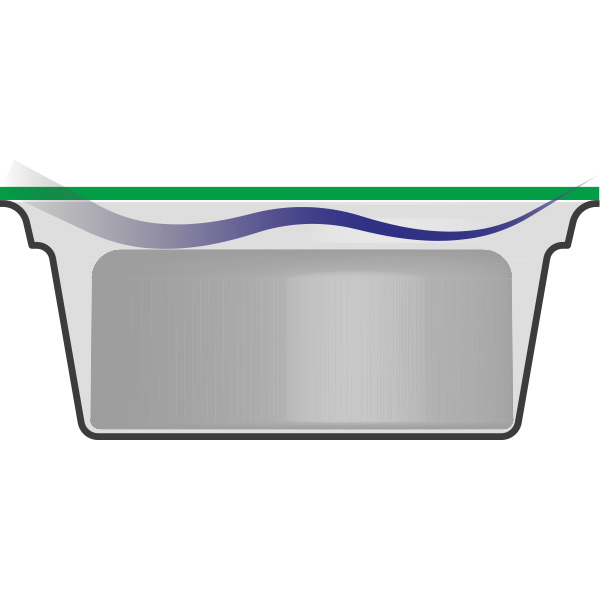

MAP/ATP

Vacuum

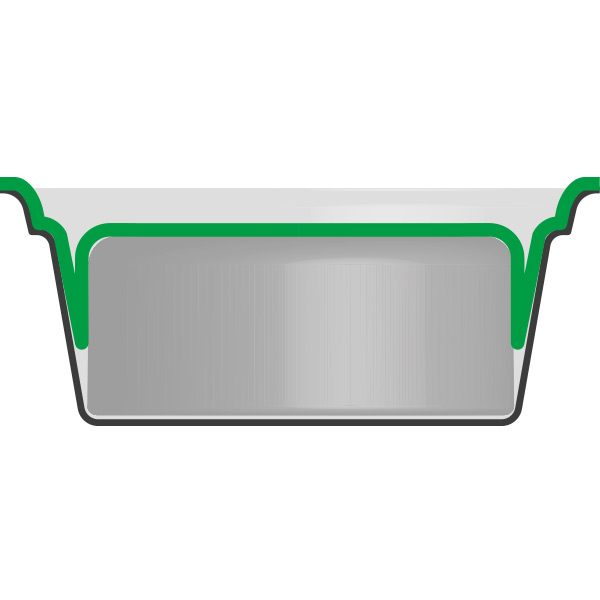

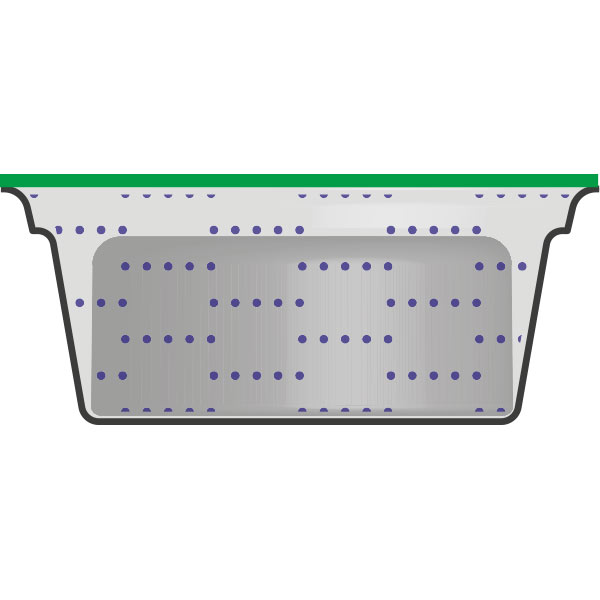

Skin

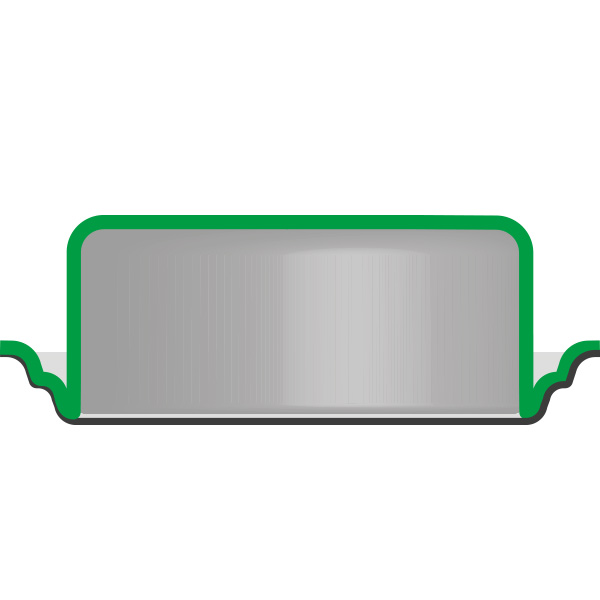

Overskin

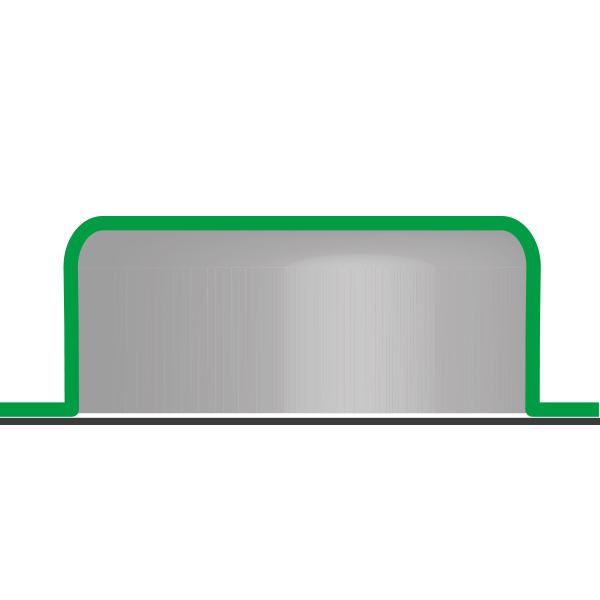

Extraskin

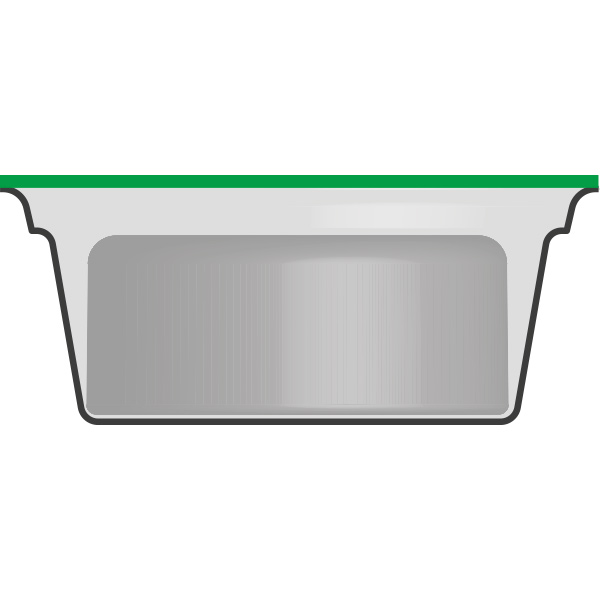

Extraskin on Cardboard

Sealing

Up to 17 cpm

Gas Flush

Up to 15 cpm

MAP/ATP

Up to 12 cpm

Vacuum

Up to 12 cpm

Skin

Up to 8 cpm

Overskin

Up to 7 cpm

Extraskin

Up to 6 cpm

Extraskin on cardboard

Up to 6 cpm

Technical Data

Technical Data : FoodPack Speedy Duo

Dimensions: 323 x 103 x h 158 cm

Weight: 720 (N) / 800 (VG) Kg

Air Consumption: 6 bar - 70 (N) 75 (VG) Nlt/cycle

Sealing Area: 380 x 270 x h 135 mm

Videos

Technology

PROGAS System

This system effectively reduces gas usage while increasing operational speed, making it a sustainable and efficient choice for various packaging processes.

Optional: ExtraSkin System

Enhances the machine’s capabilities by allowing for advanced Skin packaging, suitable even for products with high protrusion, adding versatility to its packaging options.

Optional: Pre-Heating System

Optimises the skin packaging process by pre-heating the film, ensuring a more efficient and consistent packaging quality.

DETAILS

End of Line Add-Ons

Browse Compatible Machines

From palletizers to labellers, finalise your production line with automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.