In Line

Paper Shape Line

Full Description

The Paper Shape Line is a fully automated tray forming and preparation line developed to support high-efficiency paper-based packaging production. Drawing on ILPRA’s long-standing expertise in tray packaging, the line has been engineered to deliver consistency, reliability, and smooth integration with downstream sealing operations.

Starting from flat, die-cut cardboard blanks, the system manages every stage of tray preparation within a controlled, repeatable workflow. Each station is designed to minimise manual handling, optimise floor space, and maintain a steady production rhythm, making the Paper Shape Line a practical choice for manufacturers transitioning towards paper packaging without sacrificing performance or throughput.

The line can operate as a standalone tray preparation system or as part of a complete packaging line when paired with ILPRA tray sealers.

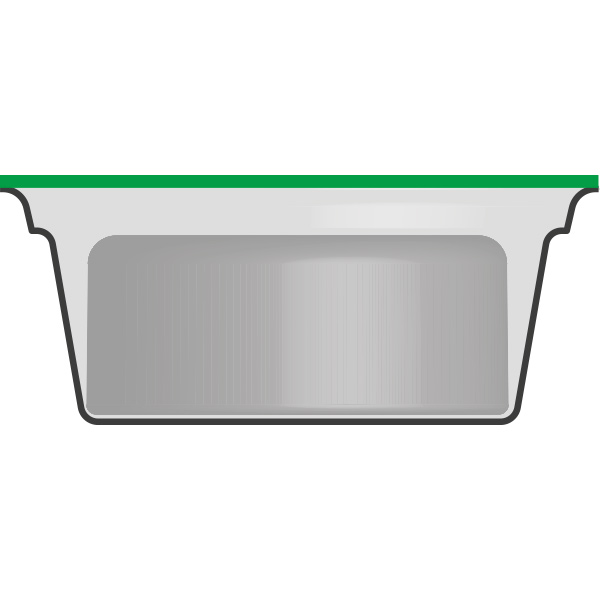

Sealing

MAP/ATP

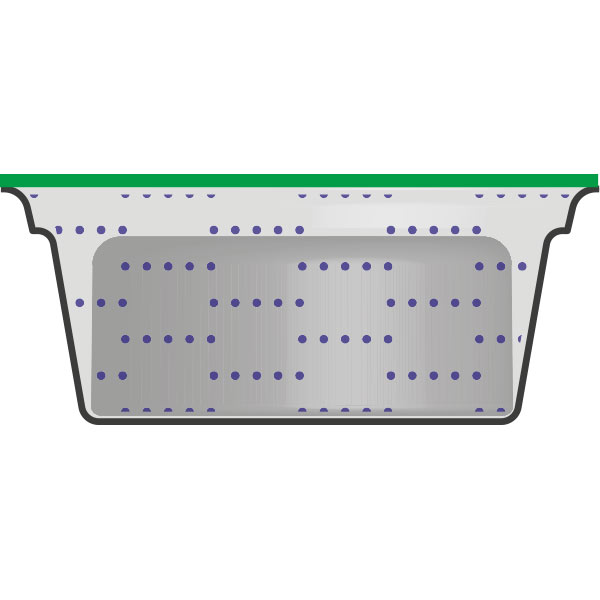

Vacuum

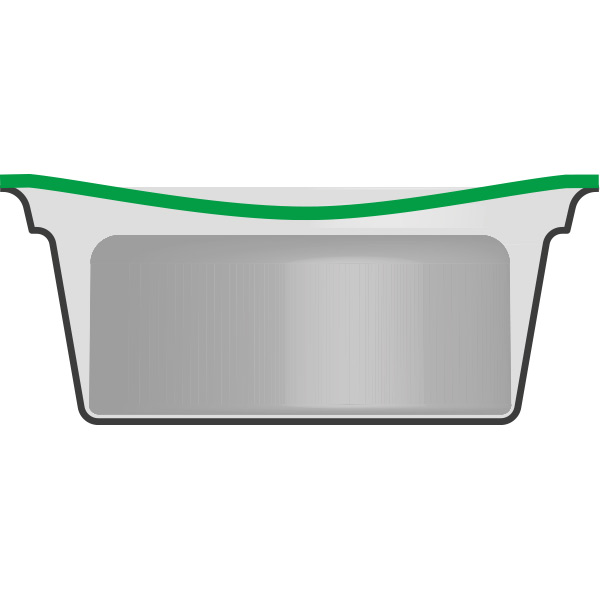

Skin

Technical Data

Integrated line design

All stations are engineered to work as a single system, ensuring smooth tray transfer between forming, lining, and stacking. This integrated approach improves efficiency and reduces bottlenecks across the production line.

High repeatability and consistency

The Paper Shape Line is designed for stable, repeatable operation, delivering uniform tray quality and reliable output throughout extended production shifts.

Flexible configuration

The line supports multiple tray formats and heights, with configuration options available to match specific production requirements and packaging formats.

Optimised workflow

By automating tray preparation from flat blank to stacked output, the line reduces manual intervention, improves space efficiency, and supports cleaner, more controlled production environments.

Designed for industrial production

Every element of the Paper Shape Line has been developed with industrial food packaging environments in mind. Robust construction, controlled movements, and synchronised stations ensure dependable operation and long-term reliability.

Built for integration

The line is designed to integrate seamlessly with ILPRA tray sealing technology, allowing manufacturers to build a complete paper-based packaging solution with consistent control and performance across all stages.

DETAILS

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.