Automatic

VKF50 Thermoformer

Full Description

The VKF50 thermoforming machine is a sophisticated machine engineered to meet the diverse packaging needs of medium-small businesses across various sectors, including food, medicine, and consumer goods.

This machine stands out for its blend of reliability, user-friendliness, and advanced technical features designed to streamline the packaging process.

The VKF50 thermoforming machine is a highly adaptable and efficient solution for packaging needs, featuring remote monitoring via a VPN protected network, tool-free quick adjustments, and robust construction with stainless steel and anti-corrosion aluminium inserts. Its user-friendly interface, designed for all levels of operators, simplifies operations, while its IP66 rating ensures it withstands rigorous sanitisation processes.

Backed by a 36-month warranty and comprehensive international support, the VKF50 sets a high standard for reliability, durability, and ease of use in challenging production environments.

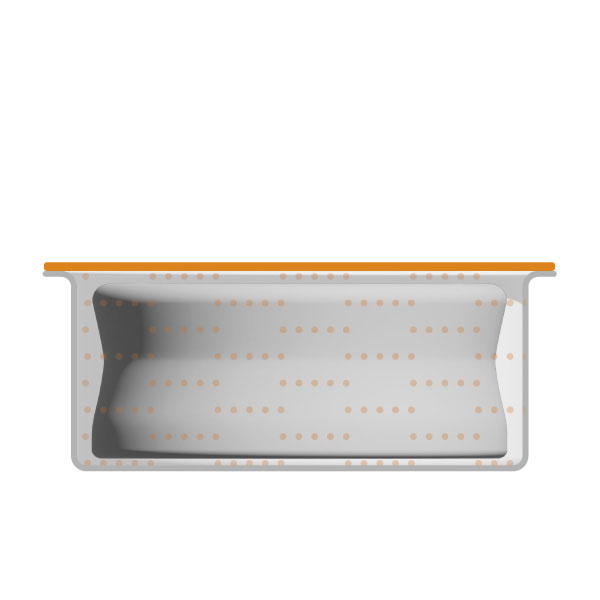

Skin Form

Sealing Form

MAP/ATP Form

Vacuum Form

Technical Data

Technical Data : VKF50 Thermoformer

Machine Length: From 4185 to 7185 with step of 600 mm

Machine Width: 1190 mm

Machine Height (Luminous Turret Excluded): 1970 mm (± 50 mm)

Loading Area: 750 ÷ 3600 mm

Loading Area Height: 950 mm (± 50 mm)

Machine Weight (Vacuum Pump Excluded): 1000 ÷ 1500 Kg

Control Panel Height: 1500 mm (± 50 mm)

Lower Film Standard Width: 322 - 362 - 422 mm (+1 mm

Lower Film Special Width: Not available

Feeding Max. Step: 480 mm

Forming Max. Depth: 150 mm

Film Reel Core Diameter: 3" (70 ÷76 mm)

Lower Film Reel Max. Diameter: 400mm

Upper Film Reel Max. Diameter: 400mm

Construction: STAINLESS steel Aisi 304

Control / Command System: PLC and Touch Screen 7"

Control / Command Interface: HMI Simatic Siemens - Windows CE

Feeding System (Drive): Brushless Motor

Installed Power (Pumps Excluded): 13-20 kW - 440 V - 50/60 Hz - 3P+N+GND

Protection Degree IP / NEMA: IP 66 / NEMA 4

Pneumatic Feeding (Average Consumption): 1250 Nl/min

Electrical Components: Siemens, Toshiba, ABB, Sick, Phoenix Contact

Mechanical Components: Rossi motoriduttori, Minimotor, Siemens, Iwis, SKF, Igus

Pneumatic Components: Festo, Parker

Vacuum System Components: Omal, Valvaut, Maros Engineering, Trelleborg

Packaging Details

Production capacity: Up to 14 cycles / min.

Application: Sealing, Skin, MAP, Vacuum

Lower film for rigid packages: Up to 700 µm (PET, PVC, PS, PP)

Upper film for rigid packages: Not available

Lower film for flexible packages: Up to 400 µm (PA, PP, Paper, Alu)

Upper film for flexible packages: Up to 200 µm (PA, PP, Paper, Alu, Tyvec, Skin)

Technology

Internet Connectivity and Monitoring

The VKF50 features a system for connection and remote monitoring via a VPN protected network. This functionality allows operators to oversee the machine’s performance and address any issues remotely, enhancing operational efficiency and minimising downtime.

Tool-Free Management

This machine offers swift and straightforward management and format changes without the necessity for tools. This feature significantly reduces the time and effort needed for adjustments, making the machine highly adaptable to a variety of packaging needs and boosting productivity.

Robust Construction

Built from stainless steel with aluminium inserts, the VKF50 is designed to endure the most demanding production environments. The aluminium inserts are treated with anti-corrosion and anti-wear hard anodising, ensuring the machine’s durability and reliability under intense stress.

User-Friendly Interface

Equipped with a colour touch screen control panel, the machine is operated through a graphically intuitive Human-Machine Interface (HMI) that is comprehensible at all operator levels. Developed in Windows CE on SIEMENS SIMATIC systems, this interface simplifies the operation, making it accessible to users with various levels of technical expertise.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.