Ready Meals

Ready Meal Packaging

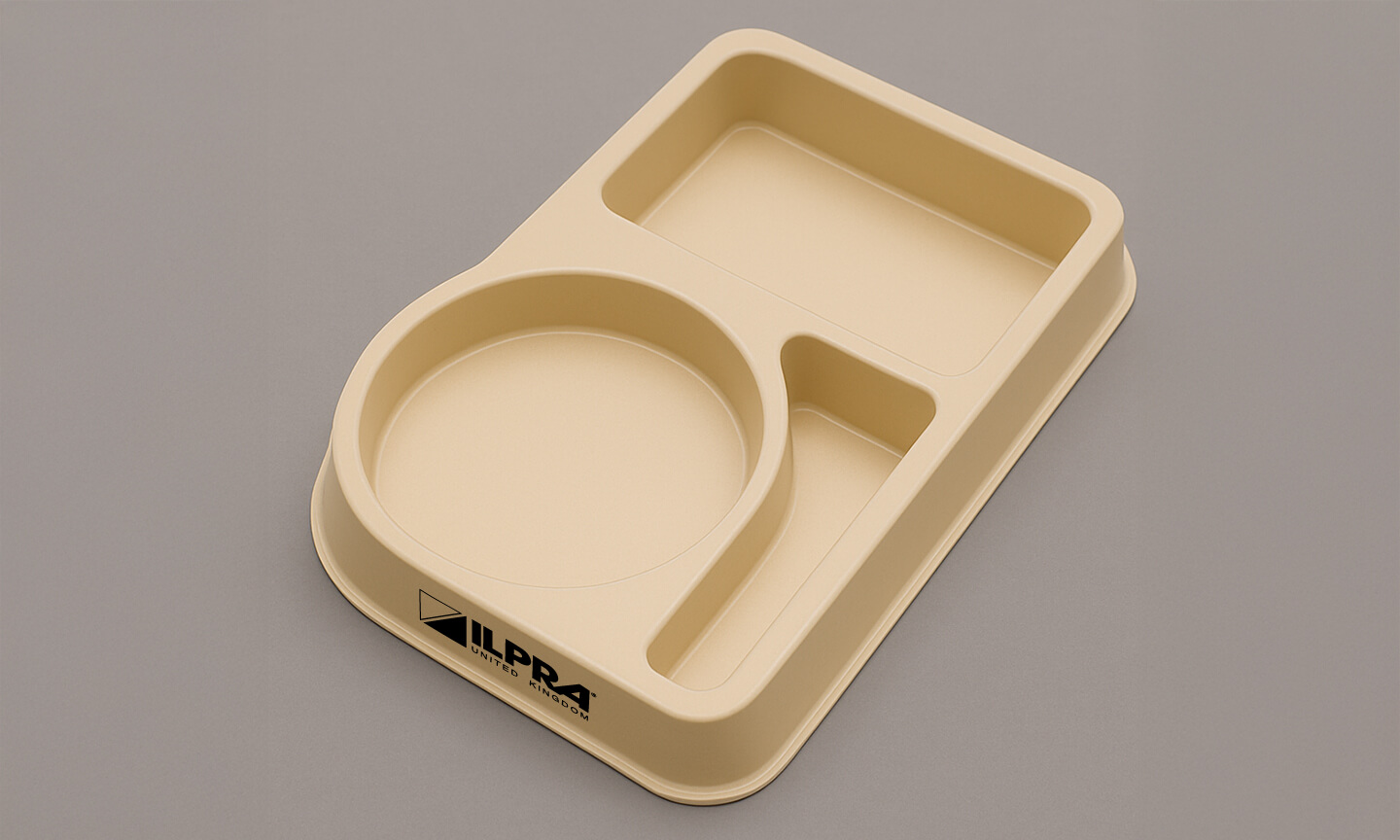

Our systems handle chilled, frozen and ambient-ready meals with options for single-serve, multi-compartment and family-sized portions.

Mono-Material Packaging

Industry Standard Trays

Film Laminates

CPET Trays

Cardboard Skin Trays

Cardboard Trays

Sachet Film Rolls

Gastronome Trays

Rigid Films

Paper Pots

Plastic Pots

Precut Lids

Self-Ventilating Film

Compostable Film

Compostable Trays

Sugar Cane Tray Packaging

Paper Shape Trays

Paper Tray Packaging

Flow Wrap Film

Premade Pouches

Shrink Wrap Rolls

Aluminium Trays & Pots

Aluminium Film Roll & Pre-cut Lids

Sandwich Packaging Boxes

Custom Packaging Trays

Plastic Bucket Packaging

Cardboard Sleeve Packaging

Wooden Packaging Trays

HDPE Packaging

Labels for Packaging

Packaging Machines

Packaging Machines for Ready Meals

All systems can integrate dosing, multi-head weighing, lidding, labelling and quality control technologies to streamline production.

View all available productsFAQs

Frequently asked questions

What types of ready meals can your machines package?

We supply machines which package chilled, frozen and ambient meals including pasta dishes, curries, stir fries, salads, noodle bowls, roast dinners and multi-compartment combinations. Systems are configured to handle sauces, high-moisture foods and delicate toppings without damage during sealing.

Which formats are best for chilled ready meals?

MAP trays are ideal as they protect flavour and texture while extending shelf life. Multi-compartment trays keep components separate until serving. Skin packs can be used for premium products that require a secure, attractive display.

Can your machines run oven- or microwave-safe packaging?

Yes. We work with rPET, CPET and pulp-based trays that are heat-safe for both ovens and microwaves. We test all formats for performance under your heating and sealing conditions.

Do you offer sustainable ready meal packaging?

We do. Options include recyclable rPET trays, mono-material lidding films, pulp trays and compostable solutions. We verify sealing performance, barrier properties and compliance with food contact regulations before production.

What UK support do you provide?

We offer installation, operator training, aftercare and spare parts supply from our UK base. We can run pre-installation trials with your recipes and packaging materials to confirm sealing quality, shelf life and presentation before going live.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.