For packaging single and multipacks of liquid products.

PACKAGING

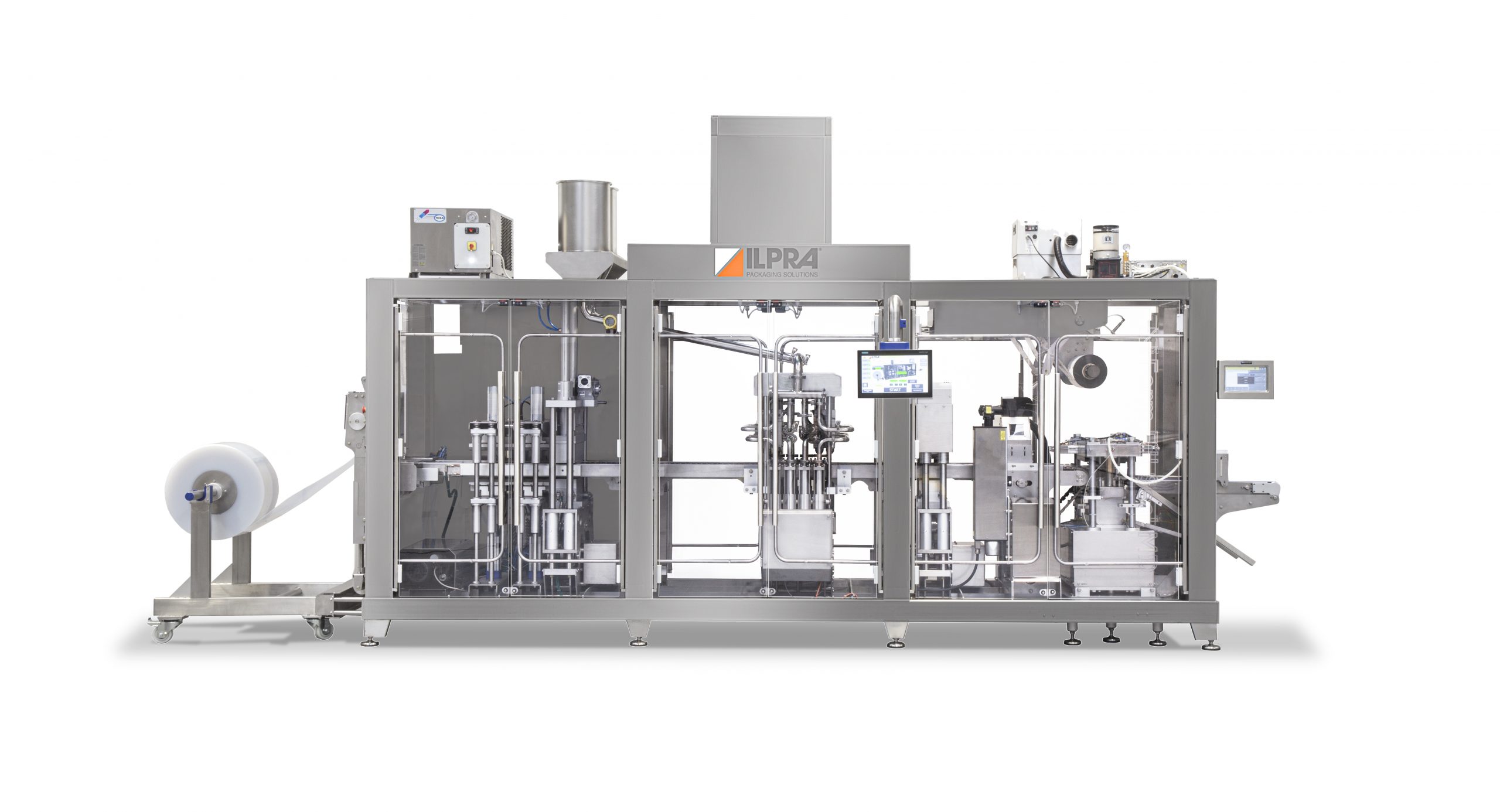

FORM FILL SEAL MACHINES

- Form Fill Seal

ILPRA’s Form Fill Seal line is designed and manufactured for different categories of productions, particularly suitable in the packaging of dairy products, sauces, yogurts and single-dose products. Starting from the long experience in thermoforming, our team of product managers has applied the latest technological innovations related to food packaging, to obtain a reliable and high-performing product. These machines are fully customizable in terms of design, dosing systems and cutting configuration, allowing both individual and multi-pack packaging. The main movements are servo-driven, ensuring maximum precision, reliability and efficiency, enabling high-level production performance.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.

No results found.